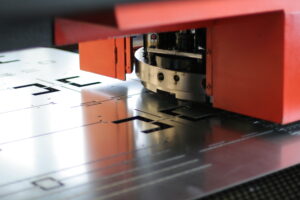

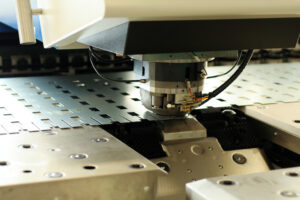

Stamped metal components form the building blocks of vehicles, equipment, electronics, appliances, tools, and so much more. Precision metal stamping processes employ a wide range of specialty equipment to cut, pierce, bend, and form sheet metal to meet modern needs. Steel and steel alloys, brass, aluminum, and copper are all popular materials for stamping projects,…

A Closer Look: How Metal Stampings Work

Metal stamping is used across a huge range of industries. Original equipment manufacturers (OEMs) typically utilize metal stamping to produce parts in situations in which casting would be too expensive. Metal stamping is much more cost-efficient, as sheet metal is easily recyclable. OEMs, especially those in the automotive, appliance, and aerospace industries, often drive the…

Metal Stamping Quality Control

When selecting metal formed parts, it’s critical to partner with a reliable, knowledgeable manufacturer who employs comprehensive quality assurance processes. This will help ensure you receive the highest-quality metal formed parts available, without the need for frequent maintenance or costly downtime. At American Industrial Corporation (AIC), we aim to provide industry-leading quality assurance throughout every…

How Metal Stamping Can Impact Your Bottom Line

If you’re looking to increase your bottom line without sacrificing the quality of your product, consider metal stamping. To create new components, stamping presses transform metal blanks into desired shapes through the use of a tool and die. With a variety of modifications, metal stamping can create numerous shapes for your product, giving you greater…

Three Metal Stamping Trends to Look Out For in 2017

Thanks to several innovative technological developments, the metal stamping industry has seen steady growth. Advancements in robotics, automation, and numerical controls have all helped improve stamping precision and speed, while virtually eliminating setup time. With rising global consumer demand, the industry is expected to continue riding this growth wave through 2017. Here are three major…

Metal Stamping in Aftermarket Auto Part Manufacturing

While the automotive aftermarket is just one step of a lengthy development and sales process, it is in itself a diverse field, encompassing everything from entertainment features and accessories to replacement parts and car servicing. As the industry shifts, various automotive aftermarket industry trends are emerging. For instance, within the B2C auto aftermarket, sales are…

3 Steps to Sourcing Materials for Manufacturing

Sourcing materials is essential to ensuring a project runs smoothly and cost-effectively. Vendor qualification serves as an important step to ensuring a successful sourcing process. Each project requires a different set of standards and can determine a vendor’s ability to match your needs. For example, your thermoforming vendor will be quite different from your precision…

Let’s Work Together: A Message from Dave Dunn to Injection Molders

One of our most important goals is to grow our business — I’m sure that’s one of your goals, too. Every business wants to grow, but what’s the best way to make it happen? In the case of metal stampers and injection molders, the answer is very simple: Let’s work together. If we pool our…

The Automotive Industry’s Record-Breaking November

This past November proved to be one of the most lucrative and successful for the American automotive industry. With the abundance of enticing Black Friday deals and the added benefit of low gas prices for drivers, the industry experienced a record high in automotive sales for the month. In fact, November 2015 was so profitable…

What it Means to be a Single Source for Metal Fabrication

Since our founding in 1981, American Industrial Company has been at the forefront of the metal stamping industry. Metal stamping may seem like a simple one-step process, but it rarely is. There are processes that must be performed before any actual metal stamping takes place, such as piercing or blanking. After the stamping itself has…