Progressive die stamping is a fast and efficient way to fabricate sheet metal into precise parts with minimal labor and scrap material. The process involves feeding a coiled strip of sheet metal through a single machine set up with a series of stamping stations. Each stroke performs different, simultaneous operations, such as bending, punching, or coining, as the workpiece is fed step-by-step through the sequence of dies until each completed part is removed from the strip. Careful, integrated part and tooling design is key to fabricating quality parts that satisfy project requirements.

Common Materials for Precision Stamping

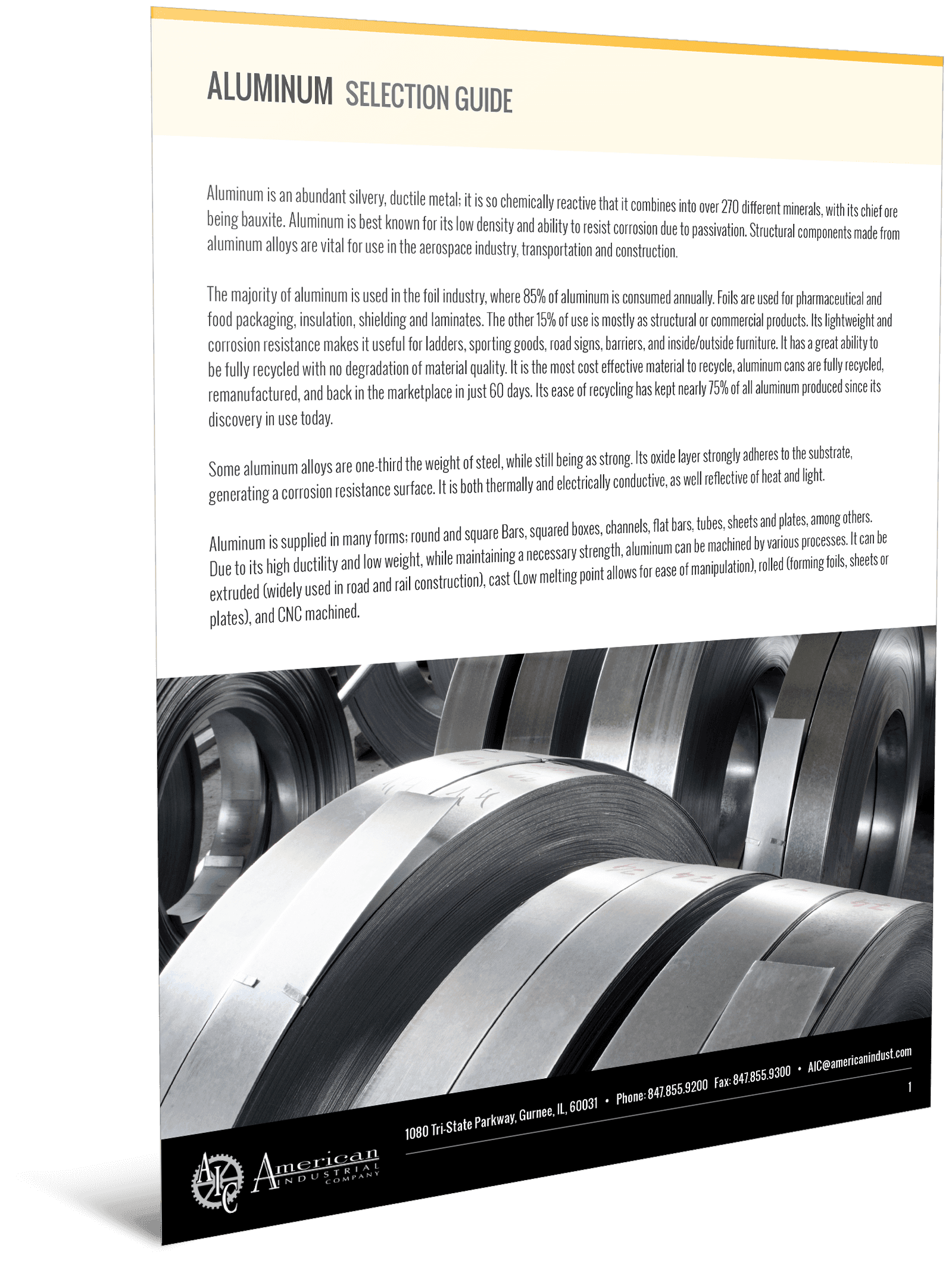

While many materials can be die-stamped, metal, especially steel, is by far, the most frequently used. Typical metals and alloys used in precision stamping include:

- Aluminum

- Brass

- Copper and copper alloys

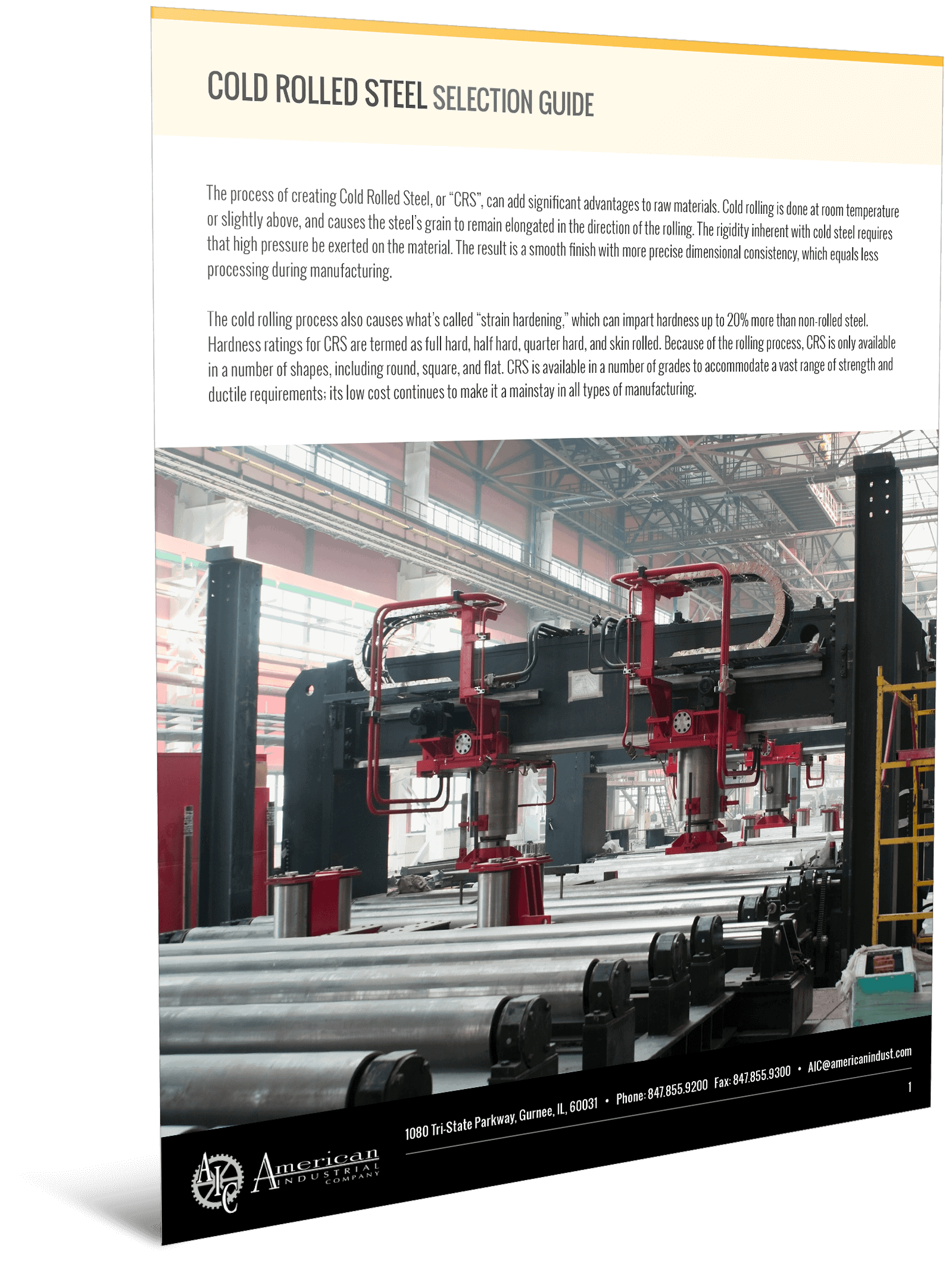

- High- and low-carbon cold-rolled steel

- Nickel-plated steel

- Pre-galvanized steel

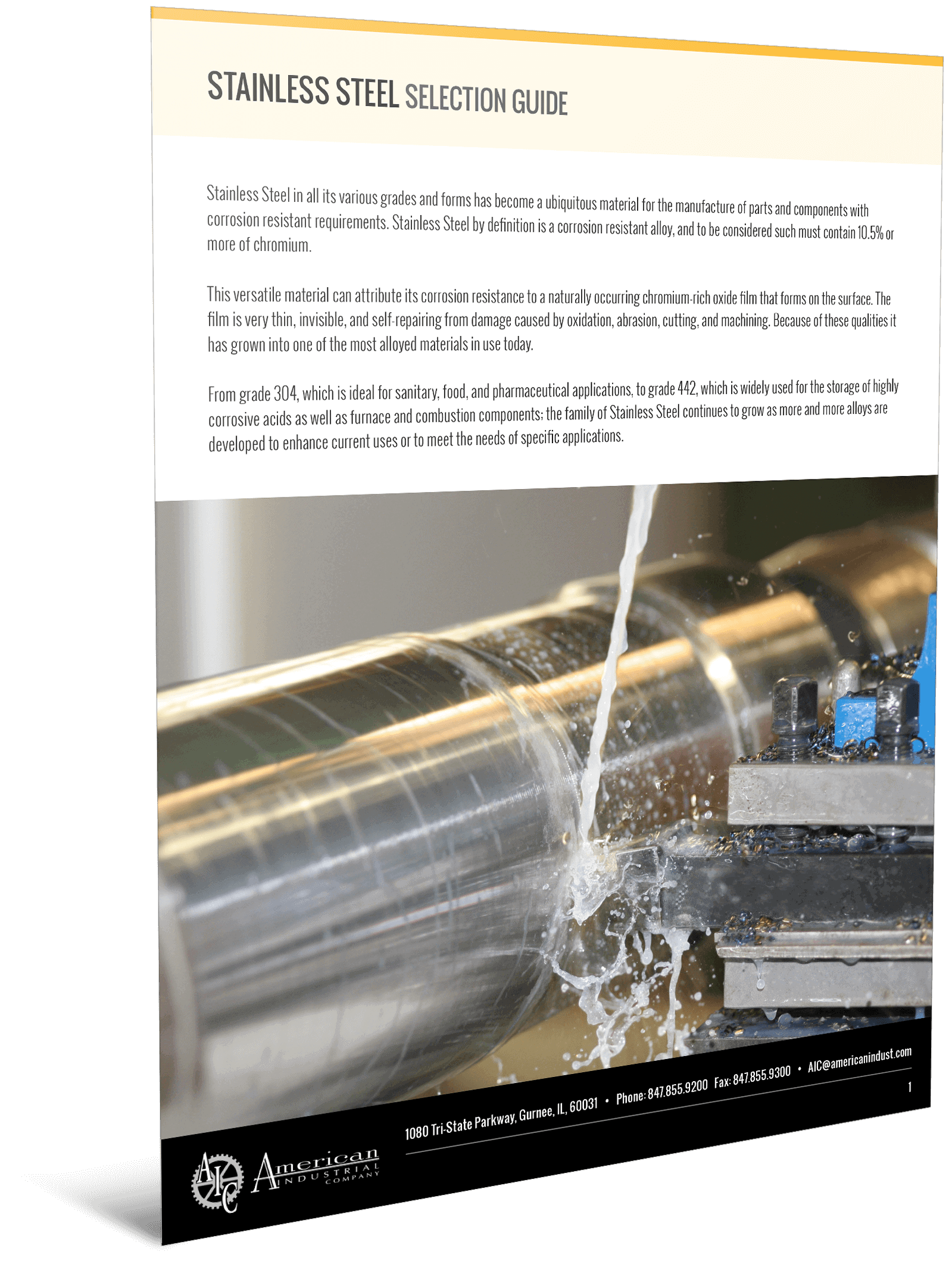

- Stainless steel

Materials should be selected to meet functional and aesthetic specifications for specific parts and projects and to satisfy any industry or regulatory requirements.

Considerations for Progressive Die Stamping Parts

Progressive die stamping is consistent and efficient and is best suited to higher volume production of small parts with more complicated geometries. When evaluating progressive die stamping as a fabrication technique for a given project, some aspects to consider are:

- Shape: Simple shapes are usually more cost-effective to make with a simple or compound die, but more complicated shapes are ideal for progressive stamping.

- Material: Metals are by far the most common material for progressive die stamping, although many polymers and other non-metallic materials can also be stamped.

- Thickness and Size: Sheet metal suitable for progressive die stamping is typically 0.001″ to 0.625″ thick. Material sizes should accommodate room to stamp parts plus enough leeway to provide support and proper alignment for the metal strip and parts as the strip is fed through the dies.

- Tooling and Order Volume: Because tooling for progressive die stamping usually costs a little more to set up than stage or transfer stamping does, longer runs of smaller, more complex parts are generally more cost-effective. Even with tooling costs, die stamping is normally less expensive than other solutions such as using a CNC laser cutting machine.

Advantages of Using Progressive Die Stamping

When used as a fabrication technique for suitable parts and projects, progressive die stamping provides many benefits over other methods, such as laser cutting services, including:

Increased Production Volume & Speed

Because production is continuous, repeatable, and automated, higher volumes of parts in longer runs can be fabricated in less time, with minimal intervention and downtime.

Reduced Material & Labor Costs

Progressive die stamping uses most of the base material to create each part, leaving little excess as scrap, and additional metal is not added to parts. With less labor needed for setup and stamping operations, fewer employees can produce more parts more safely, in less time.

Enhanced Design & Quality

Because many different operations can be effectively and efficiently combined with progressive die stamping, versatile and complicated designs can easily be fabricated. Hard, quality dies can generate these parts repeatedly and consistently over extended product runs, even with tight tolerances, maintaining quality while reducing waste.

Versatility

Progressive die stamping is an ideal solution for many industries which require efficient production of large volumes of identical, precision parts, including:

- Aerospace

- Automotive

- Consumer Goods

- Electronics

- Medical/Healthcare

- Mining

- Oil & Gas

- And more

Contact American Industrial For Your Die Stamping Parts

At American Industrial Company, we can help you achieve quality products with reduced costs per part with our progressive die-stamping solutions. Contact us to learn more, or request a quote for your next project.