Precision Stamped Metal Parts & Components

Since 1981, American Industrial Company (AIC) has been a leading manufacturer of precision metal stamping and assemblies for various industries and applications. Our family-owned and operated company strives to reduce production costs while providing quality metal stamping services.

Our turnkey services streamline supply chains and guide our customers through every step of the product development and production process. As a quality-driven manufacturer, we bring accuracy and efficiency to every project, regardless of size or complexity.

Why Choose American Industrial Company?

- Deep Expertise. We have over 40 years of industry knowledge and experience offering end-to-end services with precision metal stamping parts.

- Advanced Technology and Facilities. Our 25,000-square-foot facility conforms to ISO 9001:2015 standards and incorporates modern software such as EdgeCAM and AutoCAD. Our high-tonnage presses and metal-forming processes help create stunning products every time.

- Comprehensive Services. Our services include precision metal stamping, laser cutting, prototyping, and more. From concept design to post-production, we tailor solutions to client specifications. We can handle large-scale or custom projects, accordingly.

- Customization Capabilities. AIC can manufacture stamped metal components that meet exact client specifications. We weave these capabilities throughout the design phase, prototyping, and production to fully tailor solutions to your needs.

- Quality Assurance. We employ quality management systems to measure and define product quality. Our line of high-tech testing, inspecting, and monitoring devices seamlessly integrate with equipment. These devices include:

- Fiber Optics

- In-Die Sensors

- Infrared Retro Reflective Lasers

- Micro-Vu Matrix Optical Camera System

We back our experience, capabilities, and technologies with customer service. Our team provides flexible, responsive customer support to ensure your project’s success.

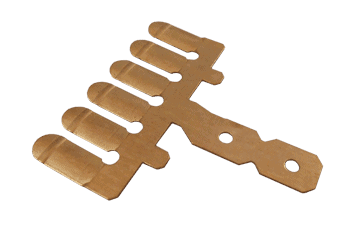

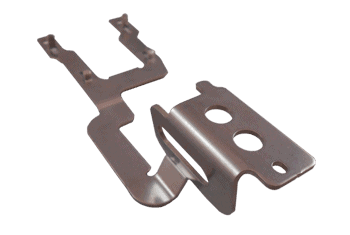

Precision Stamped Metal Parts

American Industrial Company has the resources and expertise to provide precision manufacturing of simple or complex metal stamped parts for customers across industries. Our portfolio includes a wide range of stamped metal parts including the following:

Services & Capabilities

Our high-quality services complement our unique capabilities. We offer the following services:

- Advanced Design Engineering. Advanced software tools such as EdgeCAM and AutoCAD allow us to work with complex prototypes, new or existing product redesigns. or reverse engineering methods to produce the desired product.

- Comprehensive Tooling Approach. Our expertise helps us offer optimal material and tool matching, run sizing, and specification assessments to ensure designs meet all cost constraints and address project-specific needs.

- Prototyping Services. AIC provides prototyping services for our stamped metal components, including refinement and testing of the design before production begins.

- Bending

- Blanking

- Coining

- Forming

- Piercing

- Progressive Die Stamping

- Shallow Draw Stamping

- De-Burring

- Drilling

- Grinding

- Heat Treating

- Machining

- Painting

- Plating

- Riveting

- Tapping

- Welding

American Industrial Company can handle orders of any size, from short runs to large-scale manufacturing.

Design and Engineering

- Advanced Design Engineering. Advanced software tools such as EdgeCAM and AutoCAD allow us to work with complex prototypes, new or existing product redesigns. or reverse engineering methods to produce the desired product.

- Comprehensive Tooling Approach. Our expertise helps us offer optimal material and tool matching, run sizing, and specification assessments to ensure designs meet all cost constraints and address project-specific needs.

- Prototyping Services. AIC provides prototyping services for our stamped metal components, including refinement and testing of the design before production begins.

Metal Stamping Techniques

- Bending

- Blanking

- Coining

- Forming

- Piercing

- Progressive Die Stamping

- Shallow Draw Stamping

Secondary Operations

- De-Burring

- Drilling

- Grinding

- Heat Treating

- Machining

- Painting

- Plating

- Riveting

- Tapping

- Welding

Volume Flexibility

American Industrial Company can handle orders of any size, from short runs to large-scale manufacturing.

Materials Used in Stamped Metal Parts

We have vast experience working with a wide variety of materials, some of which include:

- Stainless Steel

- Cold-Rolled Steel

- HSLA Steel

- Aluminum

- Brass

- Copper

Applications of Stamped Metal Parts

Construction Power Tools

The construction power tools industry requires stamped metal parts that meet the specific standards and demands of various construction applications. Standard characteristics of these parts include:

- Ability to withstand temperature fluctuations

- High corrosion resistance

- Optimal rust resistance

Stamped components are rarely finished after assembly. They require finishing checks, quality checks, and performance testing based on their intended use.

Hardware

Metal stamping plays a vital role in the hardware industry, generating components of varying shapes, sizes, and complexities. Common commercial and residential applications include:

- Brackets

- Catches

- Handles

- Hinges

Fastening

Metal stamped parts are a reliable, sturdy, and customizable fastening component used in various assemblies and equipment. From industrial machines to furniture making, custom-stamped metal components offer a simple, but essential, solution.

Appliances

Most households rely on appliances to perform routine tasks crucial to daily life. Consumers have a broad selection of products at their fingertips, from washers and dryers to electrical devices to kitchen equipment.

The appliance industry demands high-performance parts that are long-lasting and reliable to meet this unique demand. In addition to being functional, these parts must also be aesthetically pleasing.

Automotive

From airbag components to fuel delivery systems, stamped metal parts are found in most vehicles and are essential to the automotive industry. Major benefits include:

- Automation

- Cost-Effectiveness

- Material Efficiency

Military & Defense

Various military and defense applications utilize stamped metal components and parts in their systems and equipment. The critical nature of these applications demands stamping components that are expertly built for ultra-high reliability and precision.

Solar Paneling

Metal framing that supports solar panels can vary in strength depending on the following criteria:

- Shape

- Size

- Wind load

- Weight bearing requirements

Due to their structural diversity, solar panel frames are often customized to meet the demands of customer specifications. Regardless of the intended end use or level of intricacy, solar panel frames are typically constructed using high-alloy stainless steel and aluminum. These metal frames require numerous solar panel components such as brackets, troughs, and reflector shapes to operate successfully.

Lighting

Metal stamping’s versatility allows for a wider selection of lighting fixture parts. Stamped metal lighting hardware can include:

- Ceiling light back plates, cover plates, and mounting plates

- Light cover clips

- Metal light clips

- Quick connectors

- Recessed lighting clips and spring clips

- Rings

- Ring reflectors

Electrical

Precision metal stamping parts offer many unique benefits, making it an ideal production method for electronic components. Due to its high repeatability and accuracy, the process is the preferred choice of electronics suppliers and OEMs.

Mining

Metal stamping provides many advantages for mining industry applications, such as:

- Accuracy

- Automation

- Durability

- Efficiency

- Lower Costs

- Versatility

Marine & Naval

The following applications benefit from precision metal stamping and fabrication in the marine and naval sectors:

- Corrosion-resistant components for offshore platforms and maritime infrastructure

- Custom shipbuilding components (brackets, panels, and frames)

- Decorative accessories (custom housings, enclosures, couplings, framings, and fittings)

- Precision parts for marine engines, navigation equipment, and propulsion systems

Construction Power Tools

The construction power tools industry requires stamped metal parts that meet the specific standards and demands of various construction applications. Standard characteristics of these parts include:

- Ability to withstand temperature fluctuations

- High corrosion resistance

- Optimal rust resistance

Stamped components are rarely finished after assembly. They require finishing checks, quality checks, and performance testing based on their intended use.

Hardware

Metal stamping plays a vital role in the hardware industry, generating components of varying shapes, sizes, and complexities. Common commercial and residential applications include:

- Brackets

- Catches

- Handles

- Hinges

Fastening

Metal stamped parts are a reliable, sturdy, and customizable fastening component used in various assemblies and equipment. From industrial machines to furniture making, custom-stamped metal components offer a simple, but essential, solution.

Appliances

Most households rely on appliances to perform routine tasks crucial to daily life. Consumers have a broad selection of products at their fingertips, from washers and dryers to electrical devices to kitchen equipment.

The appliance industry demands high-performance parts that are long-lasting and reliable to meet this unique demand. In addition to being functional, these parts must also be aesthetically pleasing.

Automotive

From airbag components to fuel delivery systems, stamped metal parts are found in most vehicles and are essential to the automotive industry. Major benefits include:

- Automation

- Cost-Effectiveness

- Material Efficiency

Military & Defense

Various military and defense applications utilize stamped metal components and parts in their systems and equipment. The critical nature of these applications demands stamping components that are expertly built for ultra-high reliability and precision.

Solar Paneling

Metal framing that supports solar panels can vary in strength depending on the following criteria:

- Shape

- Size

- Wind load

- Weight bearing requirements

Due to their structural diversity, solar panel frames are often customized to meet the demands of customer specifications. Regardless of the intended end use or level of intricacy, solar panel frames are typically constructed using high-alloy stainless steel and aluminum. These metal frames require numerous solar panel components such as brackets, troughs, and reflector shapes to operate successfully.

Lighting

Metal stamping’s versatility allows for a wider selection of lighting fixture parts. Stamped metal lighting hardware can include:

- Ceiling light back plates, cover plates, and mounting plates

- Light cover clips

- Metal light clips

- Quick connectors

- Recessed lighting clips and spring clips

- Rings

- Ring reflectors

Electrical

Precision metal stamping parts offer many unique benefits, making it an ideal production method for electronic components. Due to its high repeatability and accuracy, the process is the preferred choice of electronics suppliers and OEMs.

Mining

Metal stamping provides many advantages for mining industry applications, such as:

- Accuracy

- Automation

- Durability

- Efficiency

- Lower Costs

- Versatility

Marine & Naval

The following applications benefit from precision metal stamping and fabrication in the marine and naval sectors:

- Corrosion-resistant components for offshore platforms and maritime infrastructure

- Custom shipbuilding components (brackets, panels, and frames)

- Decorative accessories (custom housings, enclosures, couplings, framings, and fittings)

- Precision parts for marine engines, navigation equipment, and propulsion systems

Get Your Project Started Today!

With over 40 years of experience, American Industrial Company provides a wide range of high-quality stamped metal parts for a breadth of industries and applications. We are fully committed to developing lasting relationships with our customers and vendors, ensuring on-time deliveries, tight tolerances, exceptional customer service, and consistency in our metal parts and components.

Contact us or request a quote to learn more about our custom solutions that can meet the specific demands of your next project.