Metal stamping is used across a huge range of industries. Original equipment manufacturers (OEMs) typically utilize metal stamping to produce parts in situations in which casting would be too expensive. Metal stamping is much more cost-efficient, as sheet metal is easily recyclable.

OEMs, especially those in the automotive, appliance, and aerospace industries, often drive the need for metal tooling. Some OEMs produce their own stamped metal parts onsite, while others outsource to Tier 1 suppliers. These suppliers build the dies for stamping down the line.

OEMs, especially those in the automotive, appliance, and aerospace industries, often drive the need for metal tooling. Some OEMs produce their own stamped metal parts onsite, while others outsource to Tier 1 suppliers. These suppliers build the dies for stamping down the line.

Metal Stamping Components and Processes

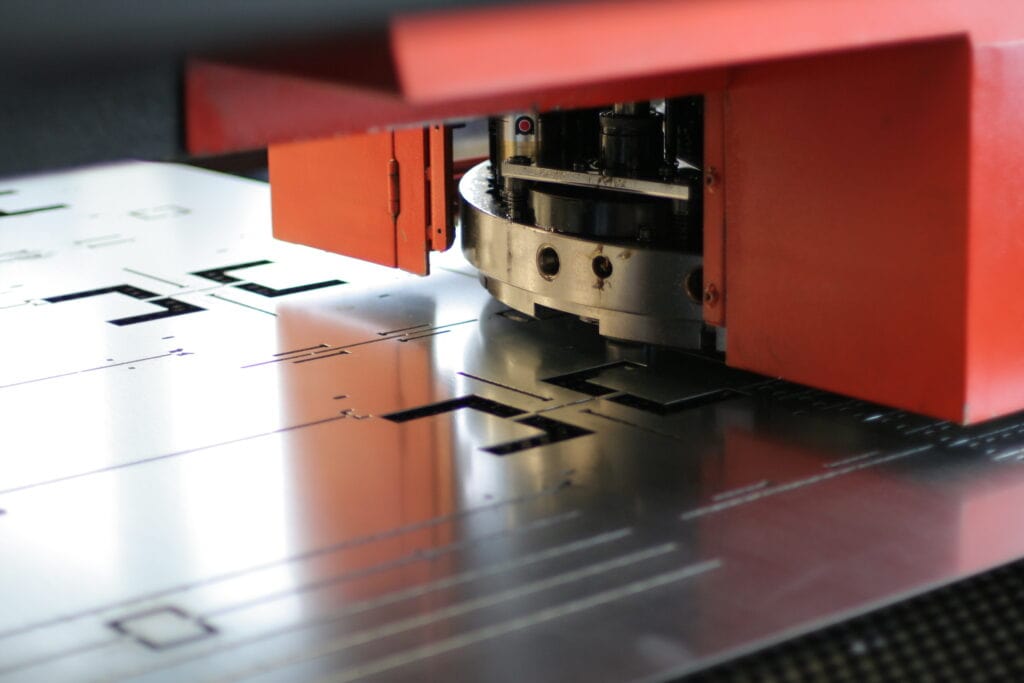

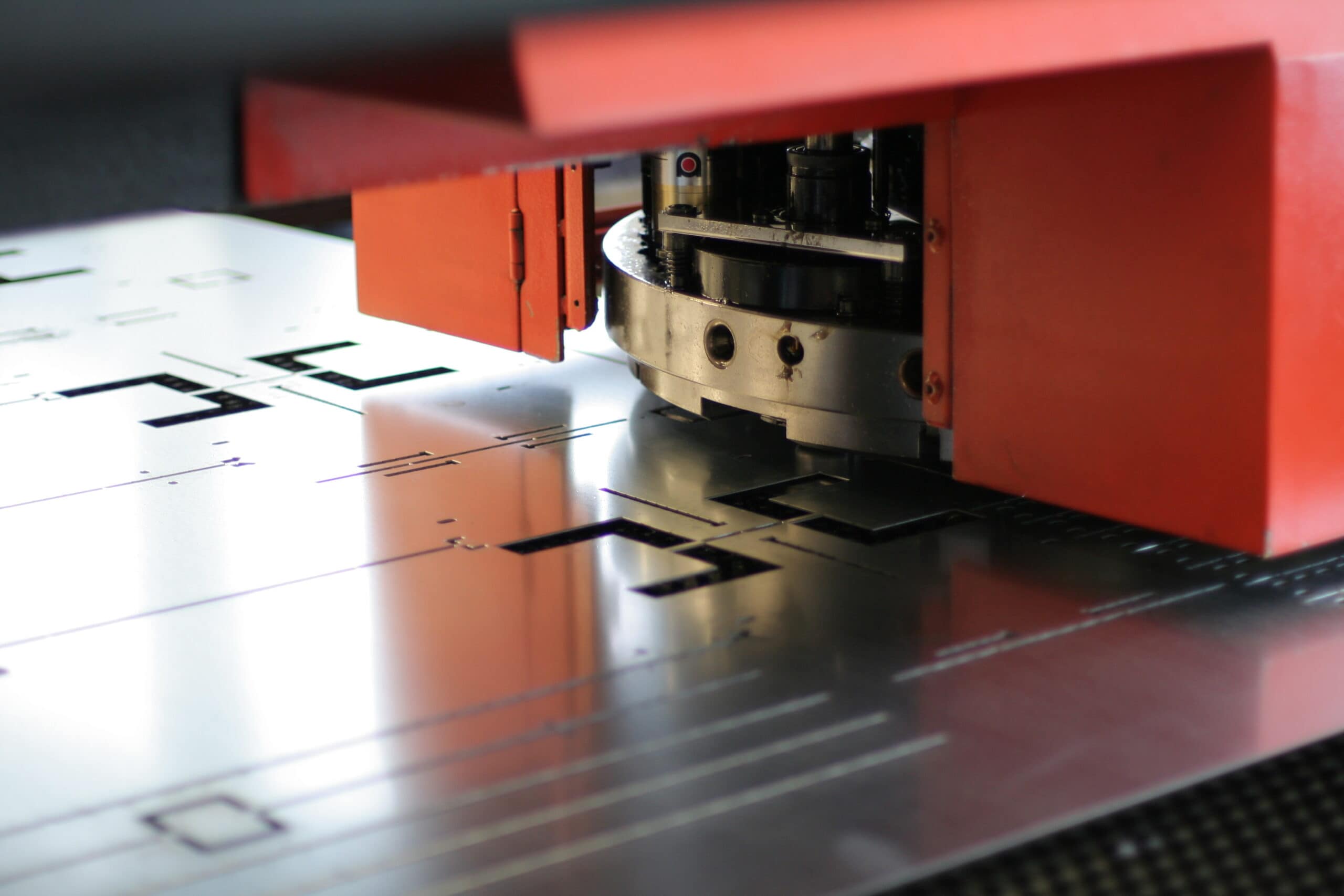

A metal stamping operation involves a metal being cut and formed into a desired shape or profile. Three basic items are essential: the metal from which the part is to be made (typically steel, though all kinds of metals can be used, including golds and advanced super alloys), the stamping press, and the stamping die. During metal stamping, a flat metal sheet, also known as a blank, is pressed between a die and a punch to achieve the desired shape.

These parts comprise the press:

- Blank — The portion of the metal that is punched through the die

- Die — Defines the outside shape of the part

- Punch — Defines the inside shape of the part

- Ram — Component that presses down on metal with upper die pattern

- Bolster plate — Stationary lower part of the die

- Blank holder — Holds the blank for control during stamping

As blanks are punched out of the sheet metal, they come through the die, which is built with a slight angle so blanks don’t get stuck inside. Punch presses are powerful machines. It takes about 71 tons of pressure to cut a 10” circle out of 0.125” sheet metal. Modern presses range from 10 tons to 50,000 tons of force.

There are a number of workers involved in the metal stamping process. A machinist cuts die components to correct dimensions. A diemaker tests dies for consistency and assembles stamping tools. A maintenance technician repairs and maintains stamping dies, correcting any problems.

Some parts require further work after stamping. During deep drawing, for instance, a flat blank is slowly drawn over a forming die to achieve the desired shape. Excess material is cut from the deep drawn metal. The metal might then need to be flanged.

Metal Stamping Services From American Industrial

American Industrial’s metal stamping services include progressive die stamping, coining or shallow draw stamping, blanking, piercing, laser cutting, bending, and forming.

Our manufacturing operations are designed for forming of a wide range of materials. Some of the most common materials we work with include stainless, cold/hot rolled and galvanized steels, aluminum, brass, copper, and high-strength low-alloy (HSLA) steel.

Metal stamping is used to create a huge range of products, including many everyday items. Common household products, such as washers and dryers, are made using a sheet metal stamping process. The flatware we use for eating, the pots and pans we cook with, and the soda cans we drink from are also manufactured partially with metal stamping.

Learn More

Ready to learn more about the uses of benefits of metal stamping? Read more about American Industrial’s metal stamping capabilities, or contact us today to discuss your specific needs with an expert.