When selecting metal formed parts, it’s critical to partner with a reliable, knowledgeable manufacturer who employs comprehensive quality assurance processes. This will help ensure you receive the highest-quality metal formed parts available, without the need for frequent maintenance or costly downtime.

At American Industrial Corporation (AIC), we aim to provide industry-leading quality assurance throughout every aspect of the metal stamping process, beginning with preproduction, continuing through operations, and culminating in final inspection and shipment.

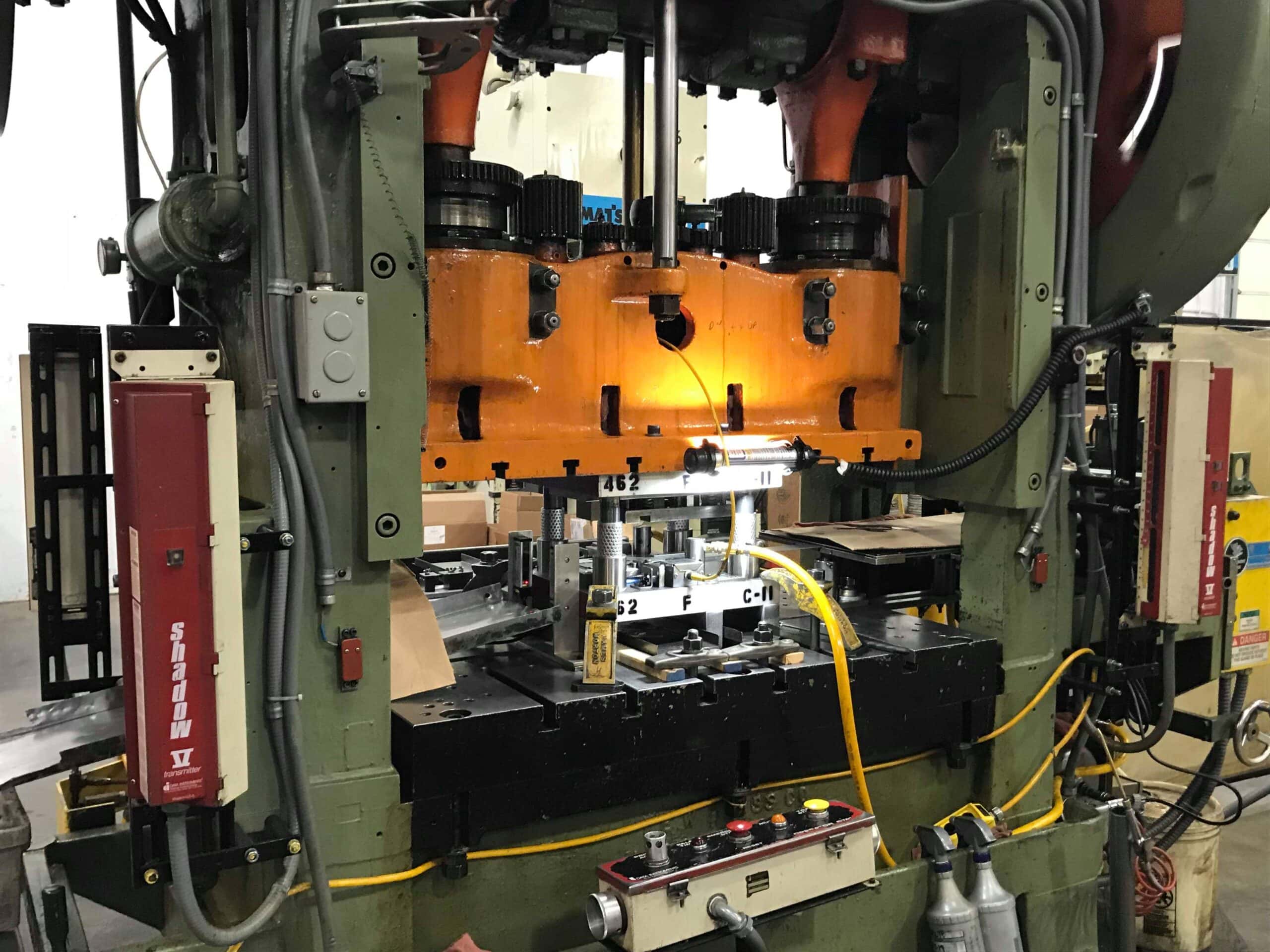

As part of this commitment to quality, we maintain the most up-to-date, cutting-edge equipment. Our team regularly inspects machinery and conducts thorough product inspections to guarantee all parts are made to exact client specifications. We also take great care in sourcing and selecting our materials, and bring unparalleled precision to our metal fabrication services.

AIC’s Commitment to Quality Control

AIC achieves stringent quality control through constant monitoring of production processes, allowing our workers to detect problems early and rectify them immediately, before serious issues occur.

Our metal stamped parts are held to stringent, industry-specific standards, which we easily meet and exceed through the utilization of sophisticated automated inspection tools — including in-die sensors and Micru Vu inspection systems — that provide instantaneous measurements.

These tools also allow records to be transmitted throughout the entire manufacturing process in order to detect variances and rectify them in real-time.

Precision Metal Forming Services Offered by AIC

The team at AIC is proud to offer a wide range of precision metal forming processes, and we are known throughout the industry for the top-quality components we produce.

Serving all types of industrial applications, we provide a wide range of services: forming and bending, progressive die stamping, blanking, piercing, shallow draw, coining, laser cutting, deburring, finishing, machining, and welding and additional secondary services.

All precision metal stamping services are performed with comprehensive monitoring, and thorough inspection of parts ensures optimal quality and accuracy. Finally, accountability testing and a lean manufacturing environment allow for streamlined, efficient operations — keeping turnarounds short and consistency high.

AIC’s ISO Certification

In 2017, AIC earned ISO 9001:2015 certification to further ensure all our products and services meet strict customer as well as the stringent regulatory requirements established by the global standards board.

ISO 9001 certification guarantees customers will receive high-quality products and services while also ensuring our company’s management and employees reap the benefits of a better-organized, safer, and cleaner workplace geared toward continuous improvement.

This certification positions AIC as an industry leader in precision metal stamping and clearly illustrates our commitment to ongoing improvement and enhanced quality assurance.

Learn More

Our ISO certification is available to download for your records. Please contact us with any questions you may have.

Watch our video: