In power engineering, busbars simplify power distribution and generation systems at the point where incoming and outgoing power meet. The experienced team at American Industrial Company (AIC) can fabricate custom busbars to your requirements for high and low-voltage power distribution applications.

We specialize in comprehensive custom progressive metal stamping, metal forming and fabrication, and laser cutting from design and prototyping through production. All parts and assemblies hold tight tolerances and are made to your exact specifications.

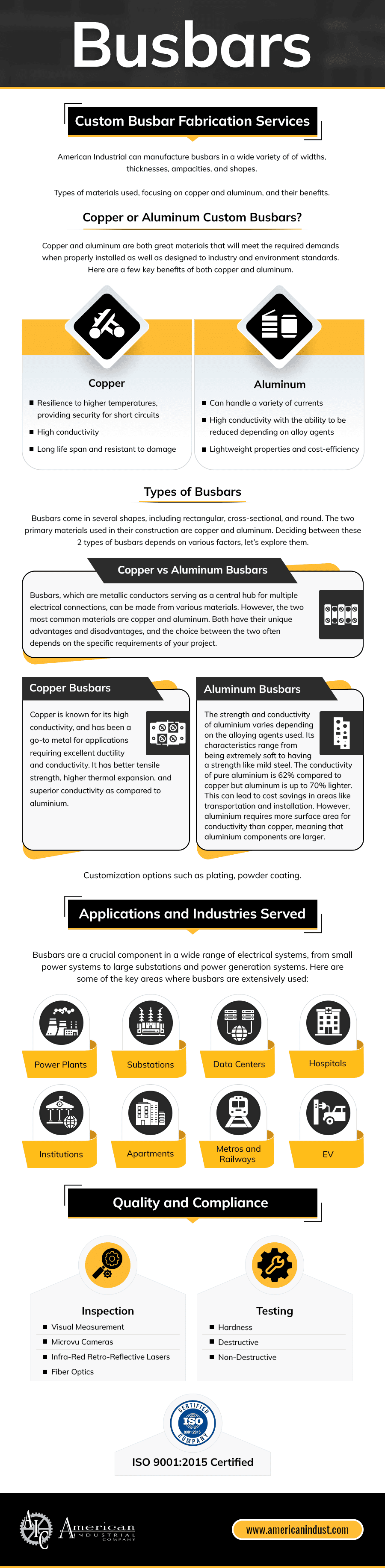

Custom Busbar Fabrication Services

Depending on the application, busbars can be designed in many widths, thicknesses, ampacities, and shapes. AIC can produce busbars with copper and aluminum materials, each of which offers excellent conductivity and recyclability.

Copper Busbars

Copper is valued for its superior electrical conductivity. It also has high thermal resistance, durability, ductility, and tensile strength. These properties ensure optimal performance in high-current applications. Copper is heavier than aluminum; however, most applications will use less copper than aluminum to achieve the same level of conductivity.

Aluminum Busbars

Aluminum is also highly conductive. It is lightweight compared to copper, cost-effective, and available in various strengths depending on the alloy used. Aluminum busbars must be used with connectors rated for aluminum. Busbars made with aluminum may require a comparatively larger component size to achieve the same conductivity as copper.

Applications and Industries Served

Busbars are critical for reliable distribution of high and low-voltage power from where it is generated to the point of use in applications such as:

- Power plants

- Substations

- Data centers

- Hospitals

- Rail transportation

- Transformers

- Large network equipment

- Cellular base stations

- Generators

- Electric vehicles

- EV charging stations

Quality and Compliance

As an ISO 9001:2015 certified manufacturer, quality is our top priority. Our team aims to exceed customer expectations with every project, ensuring all components can withstand the rigors of their intended applications without compromise.

Our standard quality assurance and control operations include:

- Regular, precise equipment calibration

- Digital vision inspection with our Microvu camera system

- Quality control testing, including non destructive or destructive methods as needed

- Thorough documentation of all inspections and testing on the part in question

Why Choose American Industrial Company

Since 1981, our family-owned and operated company has been committed to quality and customer satisfaction. We offer custom progressive stamping capabilities for busbars and a range of other metal parts or assemblies.

Our in-house end-to-end services include stamping design and engineering, tooling and die design and building, rapid prototyping, testing, laser cutting, and metal forming and fabrication.

Please contact us or request a quote to learn more and discuss your next busbar project.