A secondary operation in a manufacturing process can mean almost any post-processing requirement, and can be considered a value added service. At American Industrial Company, because we have been providing our services to so many industries since 1981, we know what secondary services our customers need the most–even the ones that are less common.

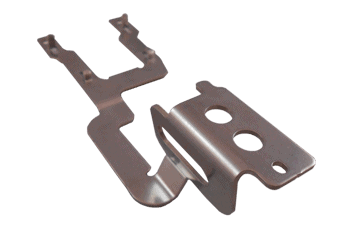

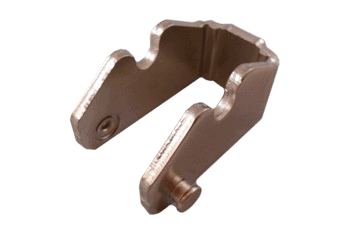

To support these requirements, we have one of the most comprehensive lists of services available in the metal fabrication industry. Chances are that if you’re looking for a vendor to manufacture a part, that part is a component of a larger assembly. What saves our customer’s time, money, and headaches is our ability to support them as a single source solution for their fabrication needs.

Value Added/Secondary Services

| Value Added/Secondary Services Specs | |

|---|---|

| Secondary Operations | De-burring Painting Drilling Plating Grinding Riveting Heat treating Tapping Machining Welding |

| Welding Types | MIG TIG Stick Spot Brazing Soldering |

| Plating Types | Electroplating Electroless Plating |

| Plating Processes | Barrel Rack |

| Painting Types | Powder Coating Wet Painting Screen Printing |

| Abrasive Blasting Media | Ceramic Corn Cob Plastic Steel Ball |

| Plating Materials | Anodizing Chromates Chromium Copper Gold Nickel Oxides Passivating Tin/p> |

| Inspection | Visual Measurement Microvu Cameras Infra-Red Retro-Reflective Lasers Fiber Optics |

| Testing | Hardness Destructive Non-Destructive |

| Documentation | Inspection Reports |

| Additional Services | Reverse Engineering Heat Treating Assemblies and Sub-Assemblies Part Inspection Design Engineering Progressive and Secondary Metal Stampings Fabrication Finishing In house Die Design and Development |

| Service Advantages | Competitive Pricing Precise and Quality Parts Prompt Deliveries Lean Manufacturing |

| Production Volume | 1 to 1,000,000 Prototyping Short Run Long Run |

| Typical Lead Time | 2 to 4 weeks |

| Stocking Programs | Dock to Stock Kanban Just In Time (JIT) |

| Additional Information: | |

| Industry Focus | Appliance – Hardware – Automotive Heating and Cooling – Construction Industrial – Dental – Lighting – Electrical Marine – Fastening – Medical – Furniture Solar – Green Building – Government/Defense |

| Industry Standards | ISO 9001:2008 Certified |

| Professional Associations | Illinois Manufacturers’ Association (IMA) Precision Metalforming Association (PMA) Tooling & Manufacturing Association (TMA) |

| Software Used | AutoCAD EdgeCAM Epicor for Manufacturing Gauge Track PC Fapt Cut |

| File Formats Accepted | DWG DXF IGES JPG TIF |

View Secondary Services Specs

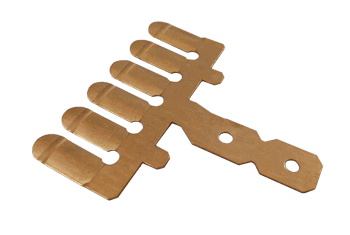

We offer a variety of welding and joining options that covers virtually every type of method; this includes MIG, TIG, stick, spot, and resistance welding, as well as brazing and soldering. Also available is a full range of plating options, from anodizing, chromates, oxides, and passivation to chrome, copper, nickel, gold, and tin plating.

These electroless and electro plating methods are carried out in barrel or rack processes that allow for the accommodation of a wide range of part sizes. Other coatings we offer include powder coating, wet painting, and screen printing which is ideal for the application of high quality logos and graphics. And no plating, coating, or paint work is complete without thorough preparation of the substrate.

To ensure the proper adhesion of any of these coatings, we also offer abrasive blasting with a selection media that is matched to the material being cleaned; this includes ceramic, corn cob, plastic, and steel ball. This ensures that only surface impurities are removed, and that the part itself in not damaged or affected in any way.

Providing all of these services is more than just an equipment list; all processes are used as part of a comprehensive production plan, and operated by skilled technicians. Diversity means nothing if it is not accompanied by quality. Our commitment to quality is backed up by our ISO 9001:2008 certification.

Secondary operations offer our customers the options that provide a complete solution for their products. With each project, we will work with you to determine the best solution to meet all of your requirements.

For further information, see the table below for a detailed description of our services, or contact us directly.