At American Industrial Company we have the skills and equipment to provide our customers with stamped and assembled components ready for the next phase of production.

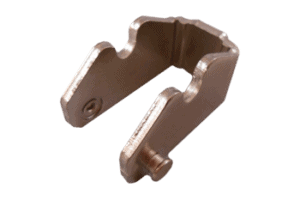

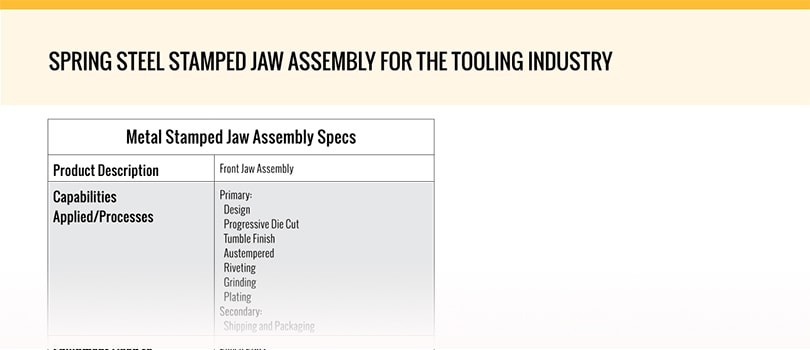

We fabricated this front jaw staple guide assembly according to very tight tolerance requirements — precision was critical for accurate actuation of the stapling mechanism. We progressive die cut C1050 spring steel into the desired form and then gave the components a tumbled finish to clean and deburr.

An austempering heat treatment to 44-50 RC improved the mechanical properties and eliminated the chances of the part distorting, even under repeated impact. We inserted the rivets, ground the components to precise dimensions and applied a bright nickel plated finish.

The assemblies pictured here featured finished dimensions of 0.9” in length x 0.76” in height, and we produced them with dimensional accuracy of ±.0002”. Our ability to develop the intricate tooling and provide multiple secondary processes enabled us to deliver 25,000 of these assemblies within the approved timeframe and at a favorable price.

To learn more about this project or the processes we use to manufacture it, we invite you to contact us today.