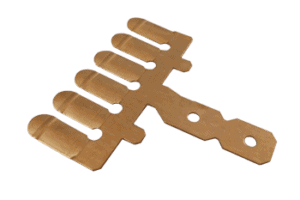

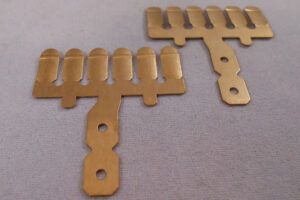

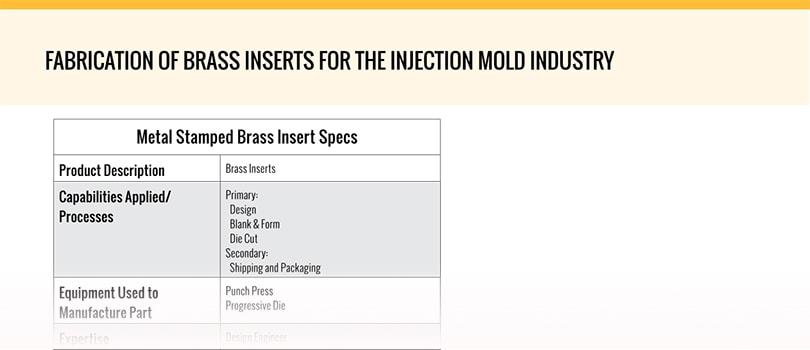

With our expertise for manufacturing small, thin gauge stamped parts with precise dimensional tolerances, American Industrial Company was contracted to produce the brass inserts shown here for a customer in the plastics industry.

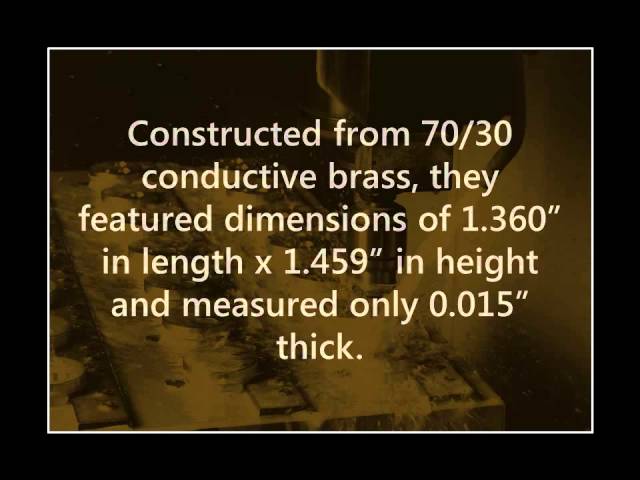

From die design and construction to blanking, forming, and die cutting, we fabricated 10,000 of these components within a two-week timeframe. Constructed from 70/30 conductive brass, they featured dimensions of 1.360” in length x 1.459” in height and measured only 0.015” thick.

Tight control of production parameters, combined with systematic in-process inspections and various other quality management tools, allowed us to achieve tight ±.004” tolerances throughout the entire production run.

To learn more about this project, or if you need a light-gauge component produced with high precision and repeatable accuracy, contact us today.