American Industrial Company (AIC) is a true single source manufacturer. With more than 30 years of tool and die and metal stamping experience, AIC has developed expertise in not just metal stamping and tooling but in all of the secondary and value added services that go along with it.

This includes all processes that require laser cutting and other custom formed components.

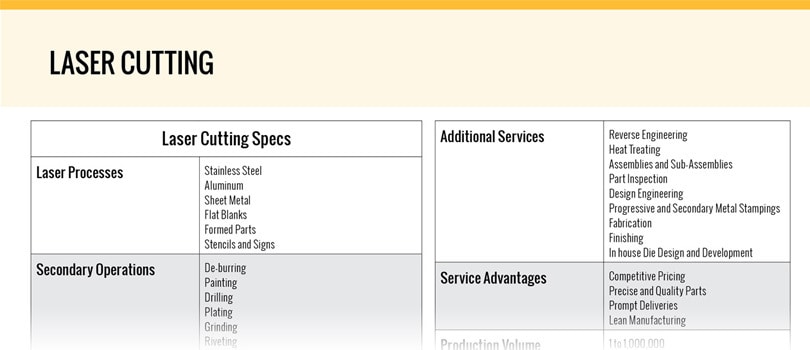

For all of your laser cutting needs, we at AIC use a VyTek FiberCAB 44 laser cutting system. This machine is one of the most highly advanced laser cutters available today. The 3,000 watt laser quickly and efficiently makes precision cuts in metals of all types.

The FiberCAB 44 uses a fiber optic laser, a type of solid state laser that is ideal for cutting metal. The fiber optic component amplifies the strength of the laser by focusing it. Fiber optic focusing allows a laser to achieve a spot size almost 100x smaller than that of traditional CO2 lasers.

The small spot size of a fiber optic laser provides high quality cut edges with minimal material warping, ideal for the food, medical, and many other industries. With the use of nitrogen, our laser cutting capabilities are perfect for stainless steel, with or without film coatings, aluminum, and steel.

What does this mean for you? American Industrial Company can provide these laser cutting services in house. Your stamped parts can be removed from the sheet cleanly, without having to go through secondary tooling processes to remove burrs.

Our fiber optic laser cutting services and capabilities are applicable in various industries, including the food, appliance, hardware, automotive, and construction industries. Not only are we a precision metal stamper of custom formed components, we can also produce flat metal parts, signs, and stencils. The possibilities are endless – with tens of thousands of digital art, silhouettes, stock illustrations, and clip art designs available.

View Laser Cutting Specs

At AIC we keep lead times short without sacrificing quality; you can rest assured that your parts will be executed flawlessly.

Fiber Optic Laser Cutting Equipment

The VyTek FiberCAB 44 laser is one of the most highly advanced laser cutting machines available. The features of this laser cutting equipment include:

- 3,000-watt laser that makes precision cuts in a quick and efficient manner in all types of metal.

- The fiber optic laser, which is a type of solid-state laser that is ideal for cutting metal.

- The strength of the laser is increased by the fiber optic component. This allows the laser to get a spot size that is 100x smaller than that of a traditional laser equipment.

- The small spot size of the fiber optic laser ensures high-quality cut edges. This results in minimal material warping

- The equipment is an ideal choice for food, medical, and other industries.

- The use of nitrogen makes it a perfect choice for aluminum, stainless steel (with or without film coatings), and steel.

Laser Cutting Methods

Different types of laser cutting methods are used to cut different types of materials.

Vaporization cutting

The vaporization method of laser cutting uses the focused laser beam to heat the surface of the material. The material is heated to the boiling point. This generates a keyhole. Absorptivity increases due to the keyhole. It also quickly increases the size of the hole. When the material starts boiling and the hole deepens, the vapor that is generated erodes the molten walls. The ejecta is blown out. This enlarges the hole. Non-melting materials (carbon, wood, and thermoset plastics) are cut using this method.

Melt and blow

High-pressure gas is used in the melt-and-blow laser cutting method. The high-pressure gas is used to blow molten material from the cutting area. This decreases the power requirement. The initial process involves heating the material to the melting point. A gas jet then blows the molten material out of the kerf. No further increase in the temperature of the material is required. Metals are cut using this process.

Thermal stress cracking

Brittle material is sensitive to thermal fracture. This feature is used in the thermal stress cracking laser cutting method. The laser beam is focused on the surface. This causes heating and thermal expansion. The resulting crack can be guided using the beam. This method is used for cutting glass.

Stealth dicing of silicon wafers

The stealth dicing process separates microelectronic chips from silicon wafers. A pulsed Nd: YAG laser is used to operate it.

Reactive cutting

The reactive laser cutting process is also known as flame cutting or burning stabilized laser gas cutting. Reactive cutting is similar to torch cutting, but a laser beam is used as an ignition source. This method is used for cutting carbon steel to the thickness of over 1mm. It is used to cut very thick steel plates.

Laser cutting is used in many industries as the possibilities are endless. It helps in keeping lead times short without sacrificing quality. This ensures that all parts are cut and made in a flawless manner.

Contact us directly to discuss your needs and what our laser cutting capabilities can do for you.