Both ferrous and non-ferrous metals are suitable for precision metal stamping, each bringing unique advantages to their end-use applications. American Industrial Company (AIC) is an industry-leading fabricator of precision, high-quality non-ferrous metal stampings with over 30 years of experience. With expertise in a wide range of industries, AIC can help you with all your stamping projects, producing high-quality results that match your every requirement and specification.

Ferrous and Non-Ferrous Metal Stampings Explained

Selecting the most suitable material for any metal stamping operation depends on the desired attributes of the finished workpiece. While there are many metal types that can be stamped, all can be categorized as either ferrous, which contains iron, or non-ferrous, which does not.

Ferrous Metals

Ferrous metals are a popular choice for stamping because their low carbon content means they are inexpensive, resulting in low unit production costs. Ferrous metals are characterized by their iron content, magnetism, and vulnerability to rust. There are hundreds of well-known ferrous alloys, specified by the amount of each element in their makeup, as well as directions on their finishing and melting.

Ferrous alloys with carbon are named iron or steel and can contain many other elements, such as aluminum or vanadium. Stainless steel, carbon steel, cast iron, and wrought iron are all types of ferrous metals. When deciding on the most suitable type for an application, mechanical properties such as ductility, weldability, elasticity, yield strength, toughness, thermal expansion, and other factors are considered.

Non-Ferrous Metals

Non-ferrous metals do not contain iron, which means they are less prone to corrosion, oxidation, and rust. They are also softer and easier to shape than ferrous metals. These characteristics make non-ferrous metals a popular choice in applications with exposure to moisture, such as liquid-carrying pipes and rain gutters. Commonly stamped non-ferrous metals include aluminum, brass, bronze, copper, silver, tin, and zinc.

Advantages of Ferrous and Non-Ferrous Metals for Metal Stamping

The characteristics of ferrous and non-ferrous metals translate to unique advantages in metal stamping operations.

Advantages of Ferrous Metals

The structure and strength of ferrous metals make them well-suited to physically demanding applications. Since they are durable and strong, they operate reliably without getting damaged. Ferrous metals are highly versatile, making them well-suited to a diverse assortment of applications, particularly engineering and industrial-related applications.

Since ferrous metals feature magnetic properties and are good conductors of electricity, they are compatible with most electrical and mechanical applications. Ferrous metals are also good for the environment since they are easily recyclable. The vast majority of ferrous metals in use today have already been recycled.

Advantages of Non-Ferrous Metals

The primary advantage of non-ferrous metals is their light weight and malleability. Another advantage is that since they feature little or no iron content, they are highly resistant to corrosion and rust. Non-ferrous metals are ideal for wiring and electronic applications due to their conductivity and are also safe to be used in explosive or flammable environments since they cannot generate a spark.

Applications of Ferrous and Non-Ferrous Metals for Metal Stamping

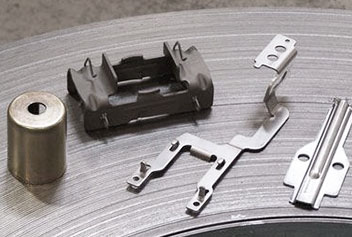

Since the metal stamping process is compatible with a diverse assortment of metals, it is used to create precision components for numerous industries.

Non-Ferrous Metals Applications

Non-ferrous metals are suitable for broad applications, from aerospace to car parts, jewelry, electrical wiring, circuitry, and more. Some specific non-ferrous metals and their applications include:

- Aluminum. Since aluminum is lightweight, it is an excellent choice for manufacturing items where weight is critical, such as aircraft. It is also used in castings, railways, cars, kitchen utensils, cans, pistons, and more.

- Copper. Copper is most commonly used by the electronics industry in wires and conductors as well as for sheet roofing, cartridge cases, bearings, and more. Copper is also used to make brass, an alloy of copper and zinc.

- Lead. This material is used in electrical power cables, batteries, construction, soldering, and more.

- Zinc. Most commonly used in galvanizing, zinc is frequently used as a protective coating to prevent rust on iron or steel.

Ferrous Metals Applications

Ferrous metals are commonly used in applications such as shipping containers, industrial piping, automobiles, railroad tracks, commercial and domestic tools, and more. Some specific ferrous metals and their applications include:

- Stainless steel. Used in medical, automotive, aerospace, and other industries, stainless steel is ideal for surgical equipment, cookware and kitchen appliances, cutlery, piping fixtures, and more.

- Carbon steel. Carbon steel is used for pipelines, structural beams, axles, gears, and other auto parts.

- High Carbon Steel. Composed of .61% to 1.5% carbon, this stronger type of carbon steel is used to make knives, drills, axes, and saws.

- Cast iron. Brittle and resistant to wear, cast iron is used in water pipes, stoves, automobile engines, machine tools, and more.

- Wrought iron. This material is often used to create fences and railings, nails, barbed wire, chains, agricultural tools, and more.

Non-Ferrous Metal Stamping From American Industrial

American Industrial is an expert in all forms of stamping, delivering precision non-ferrous components on time and at highly competitive prices. We handle everything from prototype design to production runs of up to 1,000,000 parts from our ISO 9001:2015 certified facility. For more information on our capabilities, contact us today. To get started on your next metal stamping project, request a quote.