The robustness of manufactured products are crucial to the success of mining operations, and American Industrial understands the importance of precision tools in the mining industry. The harsh environments in which workers, parts, and equipment need to operate demand durability, accuracy, and safety to ensure that operations continue smoothly and efficiently with minimal downtime.

Leaders in the American Mining Industry

Being an established manufacturer since 1981, American Industrial provides excellent quality products to our clients. As an ISO 9001:2015 certified company, we follow best practices in our manufacturing operation to ensure quality and safety.

Being an established manufacturer since 1981, American Industrial provides excellent quality products to our clients. As an ISO 9001:2015 certified company, we follow best practices in our manufacturing operation to ensure quality and safety.

These standards enable us to fabricate premier products within given design parameters using precision processes such as close-tolerance stamping and precision machining. Using hot rolled and cold rolled steel, we’re capable of meeting the stringent demands and tolerances of a variety of applications within the mining industry.

Hot Rolled Steel

In the hot rolling process, steel is first heated above its recrystallization temperature – typically above 1,000° F for most types of steel. After heating, the steel becomes malleable, which allows it to be easily molded into a wide range of desired shapes and forms. The steel contracts as it cools, which offers reduced control over the size and shape.

Hot rolled steel is recommended for:

- Large products with easily manageable tolerances

- Designs where exact dimensions are not required

- Applications with strict budget requirements

- Fabricating hot rolled bars and sheet metal for construction, welding, and other applications

Cold Rolled Steel

Cold rolled steel is a refined form of hot rolled steel. Cold rolling refers to the additional processing the steel goes through after the hot rolling process. Cold rolling involves strain hardening, which occurs when the hot rolled, cooled steel is rerolled once it reaches room temperature.

Cold rolling increases the strength and hardness of the steel, ensures a smooth finish, and allows for increased precision and meeting exact design dimensions.

Cold rolled steel is recommended for:

- Small products

- Products with demanding tolerances

- Applications that require highly durable steel

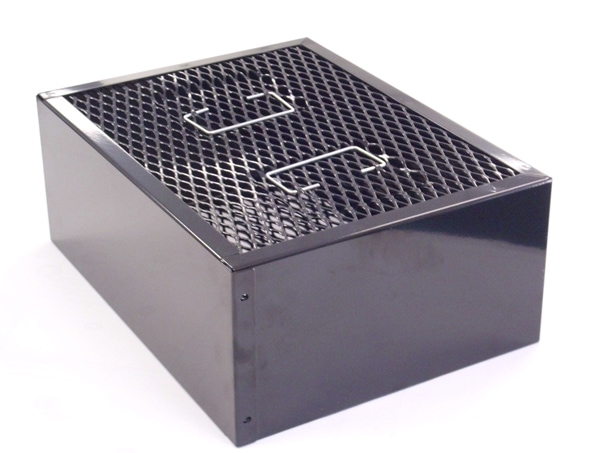

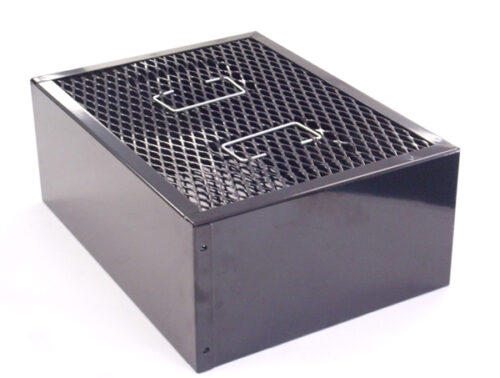

Cold Rolled Stamped Box Filter Assembly for the Mining Industry

We set our most experienced design engineers and technicians to work laying out a production plan. The box filter was manufactured from cold rolled 1008/1010 steel with 12-gauge galvanized wires. Despite the custom nature of the project, we completed design, fabrication, and delivery in only 10 days while adhering to our high-quality in-house practices.

Download our free eBook guide for comparing and evaluating the various grades, composition, and applications of cold rolled steel

AIC for the Mining Industry

American Industrial Company (AIC) is proud to be an American manufacturer and reliable contributor to the U.S. mining industry. With more than 37 years of experience in the precision metal stamping industry, we offer advanced solutions at great costs – all while providing safe environments to our workers and boosting the domestic economy.

Our ISO 9001:2015 certification attests to the quality and precision we uphold in our operation every day. Our expertise, flexibility, and experience ensure have helped us to earn the trust of clients from a comprehensive range of industries and applications.

Contact our experts today to hear more about hot rolled steel, cold rolled steel, or to discuss how we can help with your unique application,