Since 1981, we have built a solid reputation at American Industrial for fabricating precision parts for industries that demand exacting tolerances and critical dimensions. These are items that will ultimately be used in products across a wide range of industrial applications.

Our ability to fill the needs of such a vast array of applications is derived from our continual investment in our people and equipment. Our reputation as a world class provider of high quality manufactured parts has grown over the years; word has gotten around, and recently reached a customer in the golfing industry.

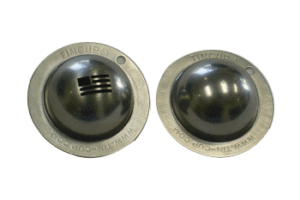

Anyone who has ever been on a green knows what a tin cup is; if you do, we’re sure that just by reading this you can hear the ball hitting the bottom of the cup after a nice putt. Like so many of the parts and components that we manufacture, they live in a world that we barely think of unless you’re tasked with getting them manufactured, or in this case, a greens keeper. This tin cup project is a perfect example.

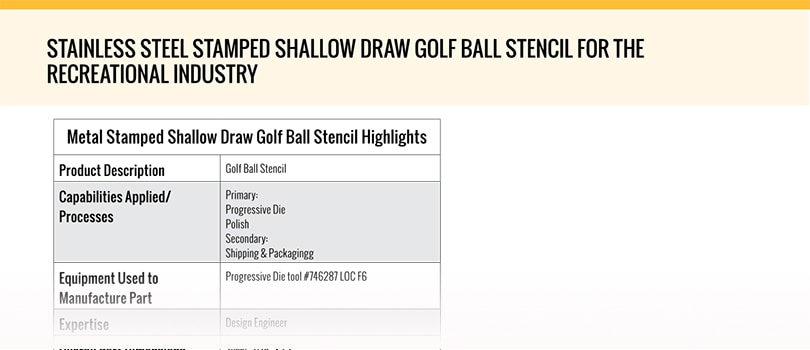

Our years of work in progressive die stamping have allowed us to develop a tool room that is vast. This resource is of great value for customers who need small amounts of a common geometry. This customer needed a single tin cup for this order, so we went to our tool room database to search for an existing die that would fit the bill. Luckily, we came up with a progressive die set that fit the need exactly.

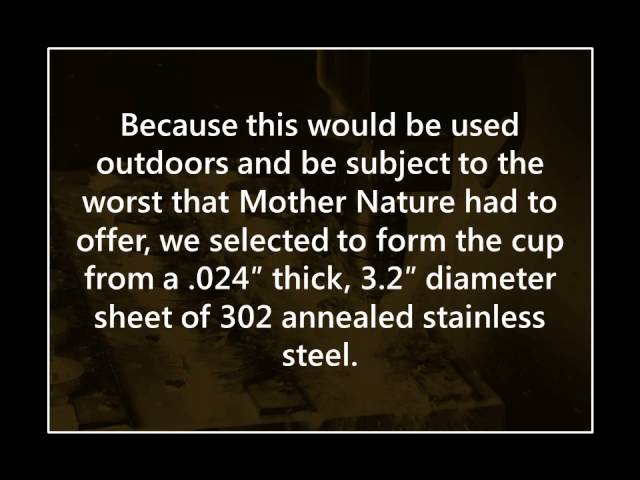

Because this would be used outdoors and be subject to the worst that Mother Nature had to offer, we selected to form the cup from a .024″ thick, 3.2″ diameter sheet of 302 annealed stainless steel. The material choice gave us and the customer a number of advantages.

For manufacturing, it provided ductility, which made for easier forming and a cleaner finish. For the customer, it provided extreme corrosion resistance, ensuring that the bottom of the cup would be clean and rust free for years to come. Once formed and inspected, we polished the cup with a bright burnished finish, then inspected it once more to ensure that it was flawless.

It was then carefully packaged and shipped to our client in Falls Church, Virginia within a turnaround time of just 10 days. All of our customer’s specifications were met, demonstrating the versatility and flexibility of our machine shop and the designers and machinists we employ.

To find out more about this project, please see the following table or contact us directly.