At American Industrial, we operate a state-of-the-art, 25,000 square foot metal stamping facility that is among the most advanced in the industry. However, the real benefit of doing business with us is working with our highly experienced staff of engineers, machinists, and technicians.

This team of specialists understands the stamping industry, and can assist your project with high quality, flexible and cost-effective production solutions. Since our founding in 1981, we’ve risen to become the go-to source for customers around the globe who need convenient precision stamping and die cutting services. One of the factors that has built our positive reputation is our commitment to quality. This is cemented by our ISO 9001:2008 certification, which is a testament to our dedication to products and processes that instill confidence with our clients.

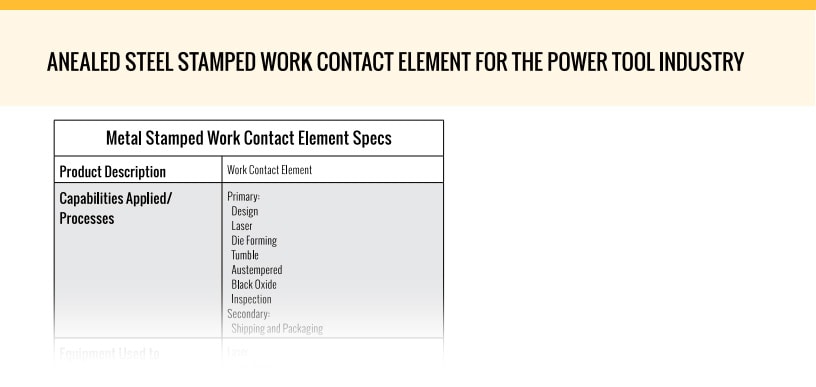

Recently, a client in the power tool industry contracted with us to manufacture the precision work contact element pictured here. This was a relatively small order, a quantity of just 750 units. However, we pride ourselves on being able to provide the same low cost, quick turnover, and superior customer service regardless of run size. After reviewing the supplied drawing, our team of engineers decided that the combination of laser cutting and die forming would achieve the most desirable and economical outcome.

The work contact element is composed of high strength 1050 annealed steel. Blanks were laser cut, followed by die forming on one of our press brakes. 1050 annealed steel is already a robust material; however, the specification supplied to us called out further hardening to bring the parts up to a 38-42 Rockwell hardness (RC).

This was followed by a very durable black oxide coating to further protect them from corrosion as well as to enhance their visual appearance. At all critical stages of manufacture, we measured and visually inspected these contact elements to ensure we met the customer’s expectations for performance and quality. Featuring dimensions of 8.00” in length, 4.00” in width, and 2.00” in height, we produced them within the ±.005” tolerance requirement.

We accomplished this project within a fast three-week turnaround. The high quality of these work contact elements satisfied our customer’s requirements in terms of form, fit, and function.

At our Chicago facility, we are able to handle commercial and industrial sized projects alike. Our staff is standing by to provide you with more information about American Industrial, the wealth of services we provide, and the products we produce.