For nearly 40 years, the team at American Industrial Co. (AIC) has specialized in high-quality, precision metal stamping. In the fastening industry, these carefully crafted parts are generally designed to be part of larger assemblies. From brackets and bolts to complex contact elements, stamped metal can make up the most intricate or the simplest of a system’s components.

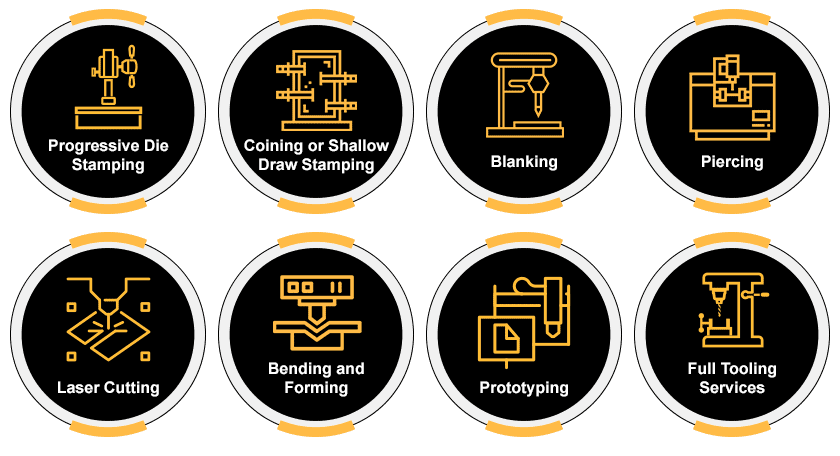

Single-Source Solutions

Our team is proud to offer complete manufacturing services for entire assemblies. For customers seeking the ease and savings of a one-stop manufacturer, we offer a range of capabilities, including:

- Progressive die stamping

- Coining or shallow draw stamping

- Blanking

- Piercing

- Laser cutting

- Bending and forming

- Prototyping

- Full tooling services

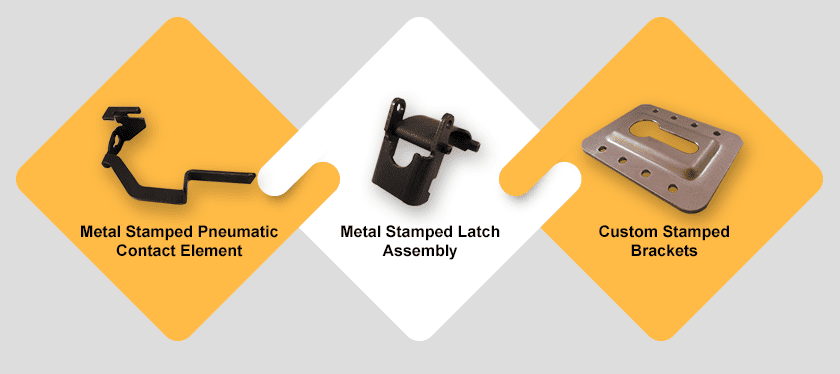

Common Fastening Applications

Critical components in countless industries, from furniture making to industrial machines, custom fastening components literally hold our world together. For complex equipment and assemblies, metal stamped parts offer customizable, reliable, and sturdy fastening solutions. To illustrate the versatility of metal parts for fastening applications, we’ve outlined a few of our past stamping and assembly projects below.

Pneumatic Contact Element for the Fastening Industry

With the use of a punch press and progressive die, AIC created a precision pneumatic contact element to fit a custom power tool.

Metal Stamped Latch Assembly for the Power Tool Industry

This latch assembly is a perfect example of a custom, precision fastening solution: It featured four discrete components for a complete, high-performance assembly.

Custom Stamped Brackets for the Automotive Industry

Part of a prototyping project, these chrome-plated brackets were crafted to safely secure floor mats in an automotive project. Spot welding, custom plating, and careful inspection processes ensured top performance for this project.

Check out our portfolios page to view more custom fastening projects.

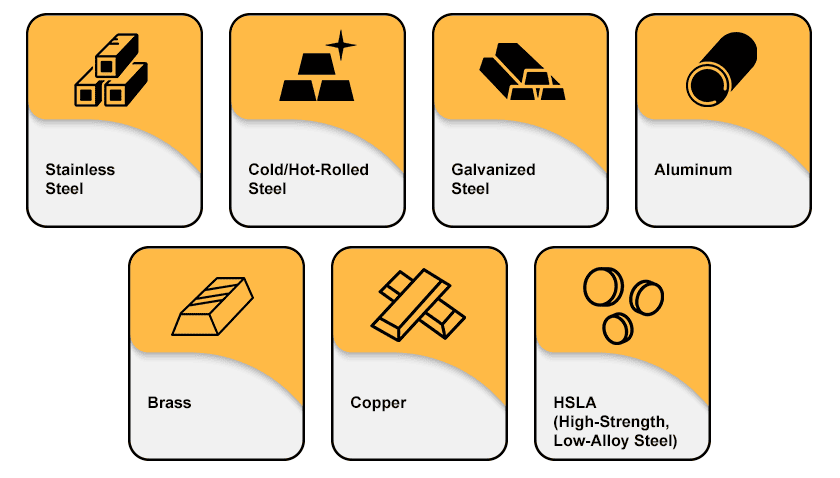

Materials

In addition to offering a complete catalog of services, AIC manages a wide range of materials to suit almost any need. Our presses and equipment are designed to form thicknesses from 0.005” to 0.188” with tolerances of 0.001”. Some of our most commonly requested metals include:

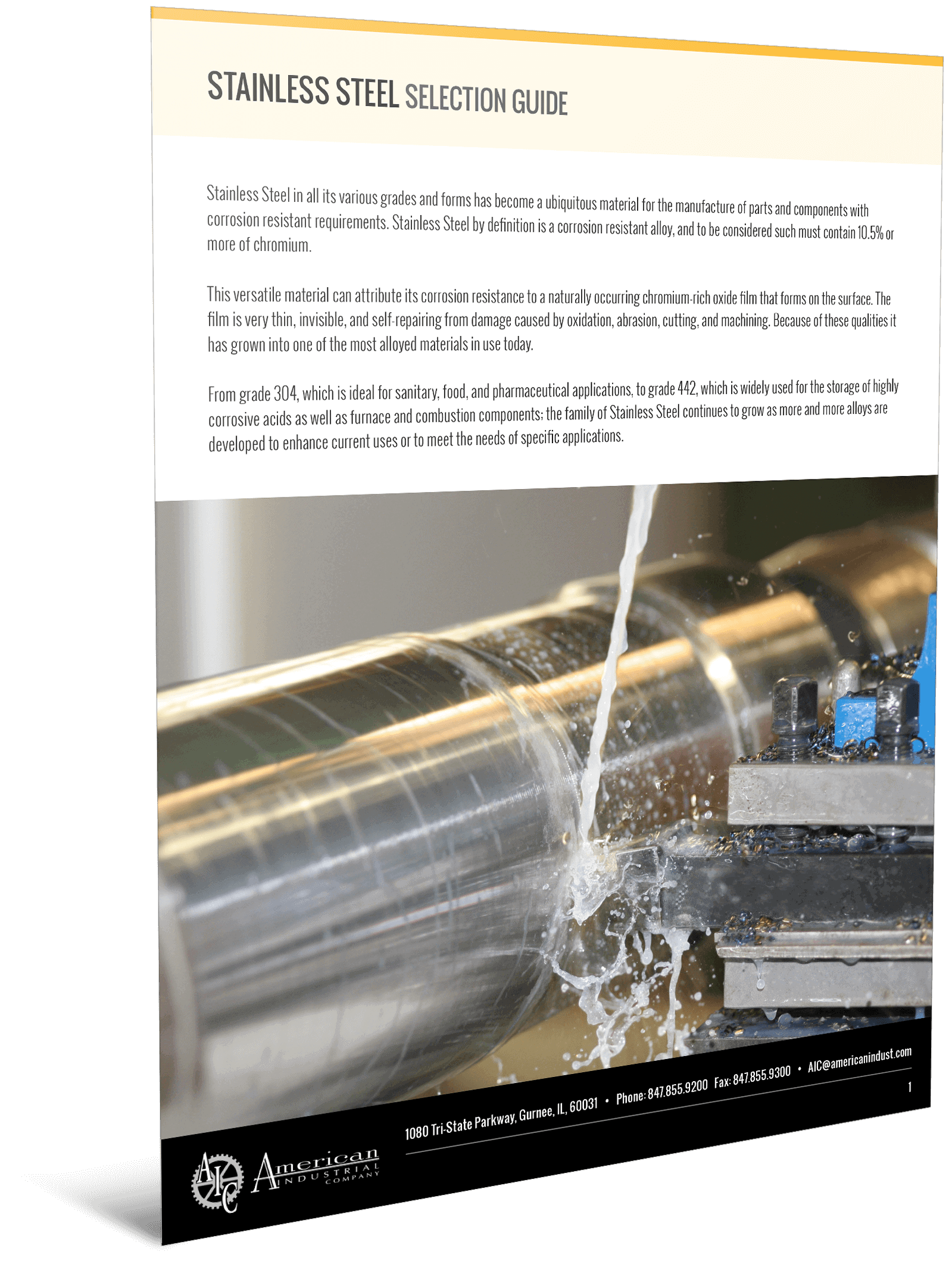

- Stainless steel

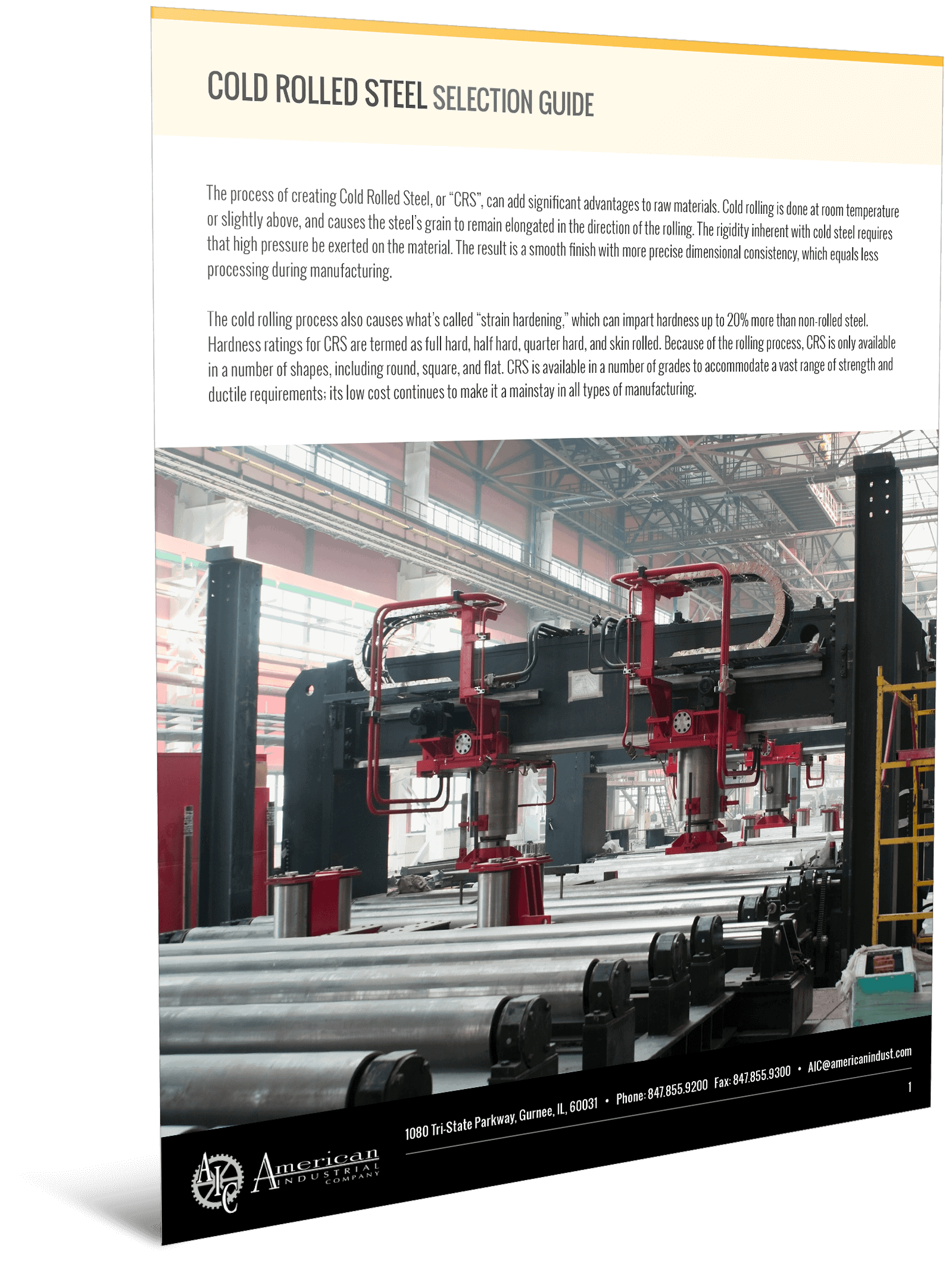

- Cold/hot-rolled steel

- Galvanized steel

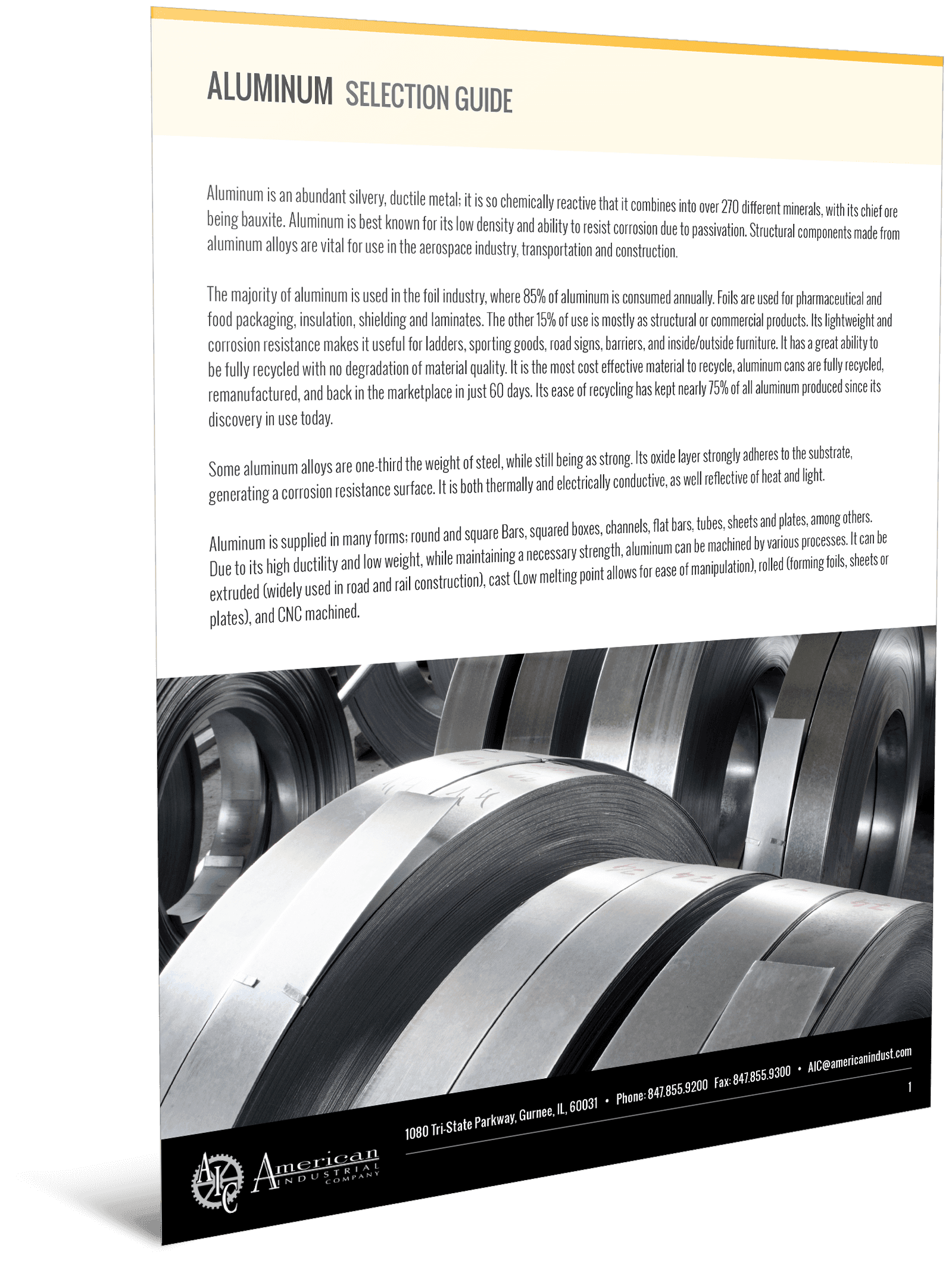

- Aluminum

- Brass

- Copper

- HSLA (high-strength low-alloy steel)

Fastener Manufacturing at AIC

Before embarking on your next precision metal stamping project, it’s critical to ensure that you’re partnering with a metal stamping company that can offer uncompromising accuracy, repeatability, and overall consistency. A reliable manufacturer will not only produce great final products but will also help you save money in the process.

Our state-of-the-art, in-house toolmaking facility — located just 30 minutes from the Chicago’s O’Hare International Airport — is supported by a full host of stamping, forming, design, and finishing services. Offering a range of capabilities, from tumbling and deburring to specialty painting, we deliver complete, high-performance products backed by ISO 9001:2015 certification.

Learn More

Selecting the right metal stamping supplier can be a tough job, but our team is ready to help. Download our free guide, outlining ways to avoid mistakes and ensure you find a reliable vendor. Or, to learn more about custom assembly fasteners and stamped metal parts or discuss your next project with an expert, contact the team today.