At American Industrial, we are well known as a major supplier of high quality metal stamping and die cutting services.

Since 1981, we’ve been providing contract manufacturing services to customers across a wide range of industries. Each project or application for which we provide stamping services is centered on precision manufacturing and superior customer service.

Part of our commitment to excellence is the ISO 9001:2008 certification of our 25,000 square foot facility, located in Chicago. This is a truly advanced manufacturing facility that is specifically designed to accommodate the production needs of high volume, complex jobs that require precision and accuracy.

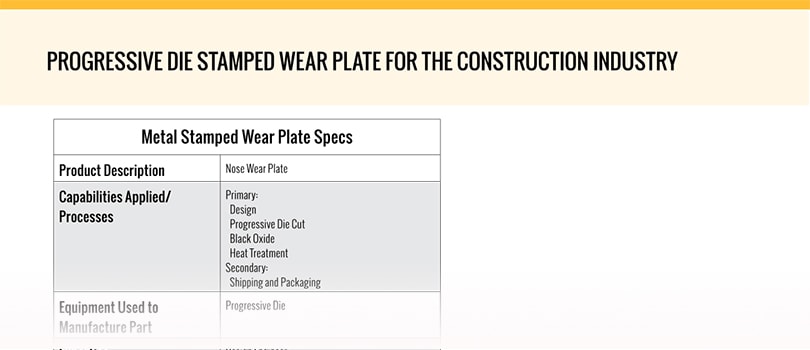

These capabilities were brought to bear in the project highlighted here. This nose wear plate is designed for use in a power tool application. It was designed and fabricated with the right combination of strength, hardness, and toughness to stand up to heavy duty use and provide a long service life.

The ingenuity of our engineering team enabled us to develop a progressive die stamping process that created all of the tight tolerance bends, angles, radii, and channels on this geometrically complex part. The wear plate was manufactured from cold rolled tempered steel.

This provided high strength and enough malleability to simplify manufacturing. The design featured overall finished dimensions of 4.38” in length, 1.562” in width, and .062” in thickness.

After stamping, we applied a ferritic, nitrocarburizing treatment which significantly improved the fatigue properties, adhesive wear resistance, and scuffing resistance without distorting its shape during the hardening process. Our experienced quality control department provided visual and dimensional inspections to confirm that we met the required ±.003” tolerances.

In the end, we shipped 150,000 units of this critical component to the customer within a two week timeframe. This order was accompanied by a comprehensive quality assurance inspection report that validated product integrity.

To learn more about this project and our ability to meet demanding production and scheduling requirements, please contact us today.