As a top provider of high quality progressive die stamping, we operate a very well-equipped, ISO 9001:2008 certified facility. This advanced capacity gives us at American Industrial the flexibility to shift our resources to accommodate quick turnaround production requests.

This ability to provide expedited production metal stamping services makes filling urgent requests commonplace. This valuable capability is highlighted in the project shown here.

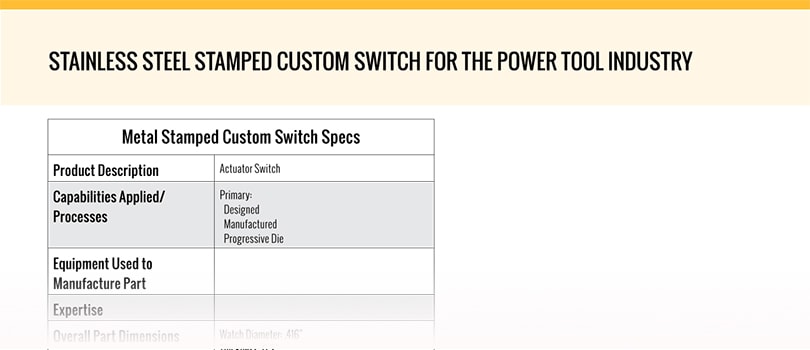

One of our long time customers in the power tool industry was in urgent need for the fabrication of a large quantity of progressive die stamped parts to keep their assembly line moving. The part, a custom actuator switch, was a repeat order; since we proactively maintained the original tooling in ready-to use condition, we were able to provide the production capacity to meet their needs.

Manufacturing was completed using our high precision progressive die stamping capabilities. The component itself is composed of ¼ hard 301 stainless steel, which was selected by the customer for its high strength and corrosion resistance characteristics; it also is malleable enough to be easily formed into the geometries necessary for this project.

The finished piece featured dimensions of 0.416” in diameter and 0.2” in thickness, and was manufactured to tolerances of ±.001”. A high level of quality was maintained during production through the use of a number of advanced sensing and measuring technologies. These included precision infrared lasers, highly accurate load monitors, and state of the art vision system cameras that enabled us to monitor both the condition of the tools and quality of the stamped product during actual production activities.

The combination of these cutting edge equipment capabilities combined with the foresight to keep tooling in ready-to-run shape allowed us to accommodate this customer’s need. This rush job of 100,000 pieces was successfully completed and delivered in just one day.

Experienced staff, high speed equipment, and the understanding that bending to meet a customer’s needs is the foundation of customer service are what make so many of our customers trusted partners.

To learn more about this project, or how our agility and responsiveness can become one of your biggest production assets, contact us today.