Nowhere is precision and robust construction more critical than in the mining industry. Parts and equipment associated with this vertical see some of the harshest working environments in existence.

In addition to these harsh conditions and severe duty, many items have an immediate impact on worker safety. This is why it is imperative to have high quality, precision practices available when manufacturing parts for this demanding industry. For this reason, our clients can rest assured that when American Industrial is involved in manufacturing, the end result will always be the highest quality that the design parameters will allow.

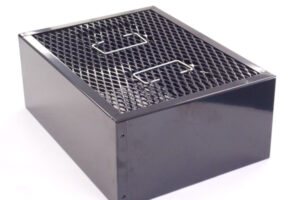

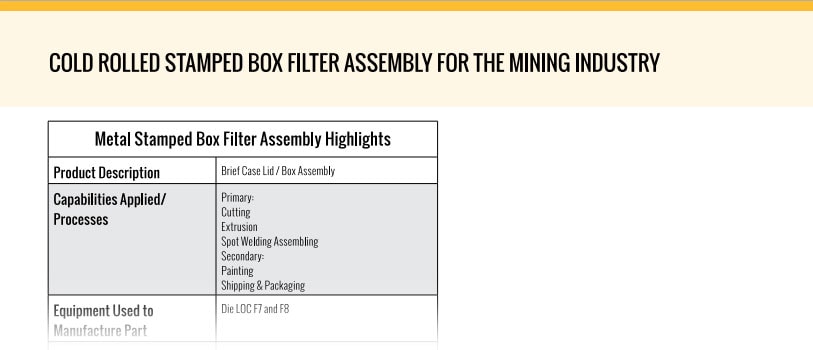

We are well known in many industries for these capabilities, especially the mining industry. In this project, a manufacturer of mining equipment contracted us to create a briefcase lid/box assembly that was designed as a filter frame. The end product’s design intent was for it to work as a box filter to protect workers and equipment from fine dust and dirt particles.

We have been providing accurate, close-tolerance stamping and machining since 1981 at American Industrial, and the critical nature of this project was an ideal match for our capabilities. We operate an advanced manufacturing facility in Chicago, near O’Hare Airport. We are geared for high volume work; however, we can also easily accommodate the manufacturing of a single part, such as in this instance.

This flexibility allows a broad range of customers to enjoy our precision manufacturing and low cost production. For this project, we employed a number of processes that were carried out by some of our most senior and experienced technicians. A design engineer was assigned to the project to lay out a production plan. This included processes such as cutting, extrusion, spot welding, painting, and assembly.

The box filter was fabricated from cold rolled 1008/1010 steel and 12 GA galvanized wire. The finished filter had design features that included a hidden handle, with overall dimensions of 11.75″ in length and 15.75″ in width. It was fabricated to precision tolerances of ±0.003″, and was finished with black beauty paint.

After thorough visual inspection, this filter was packaged and shipped to our client in Columbia, Maryland. We completed this project entirely in just 10 days, all the while adhering to the high standards required of us as an ISO 9001:2008 certified company.

For more information about this project, please see the following table or contact us directly.