American Industrial Co. is a top manufacturer of stamped components for the electrical industry, including electrical power transmission and distribution applications. With over 30 years of industry experience and deep knowledge of metal stamping for electrical applications, we have the capabilities to deliver durable, reliable components according to client specifications.

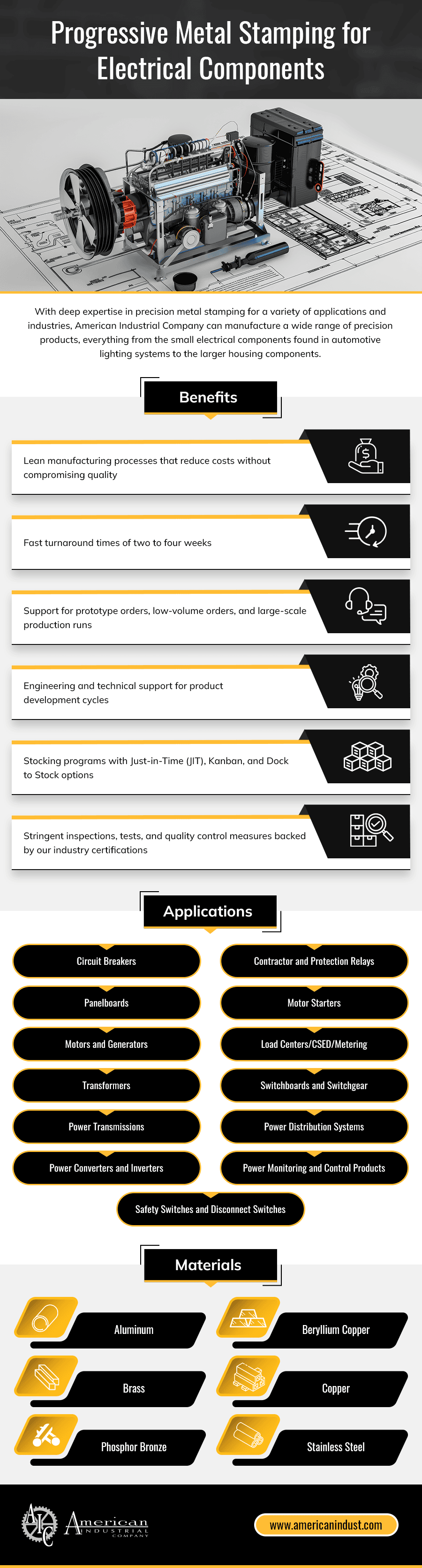

We provide metal stamped components for a breadth of applications in the electrical industry, including the following:

- Circuit breakers

- Contractor and protection relays

- Panelboards

- Motor starters

- Motors and generators

- Load centers/CSED/metering

- Transformers

- Switchboards and switchgear

- Safety switches and disconnect switches

- Power transmissions

- Power distribution systems

- Power converters and inverters

- Power monitoring and control products

We can produce a range of stamped parts for electrical applications, including:

At American Industrial Co., our numerous strengths make us stand apart as industry leaders. Our expertise and experience differentiate us, with a long history of success driven by a team of highly skilled technicians and engineers. We also offer competitively priced solutions for customers in electrical distribution while consistently meeting the strictest standards and achieving tight tolerances. Our lean manufacturing processes also help minimize waste and maximize productivity, with a two- to four-week turnaround to meet customers’ timing requirements.

We can offer fully tailored solutions for electrical applications, taking a collaborative approach to facilitate the production process. We utilize cutting-edge technologies and machinery that can handle orders of up to 1,000,000 parts to complete each metal stamping project, allowing us to handle high-volume runs and prototyping projects. We also offer Dock to Stock, Just-In-Time (JIT), and Kanban inventory management options for added flexibility.

Above all, we work to maintain the highest quality for our customers, enacting thorough quality control measures and maintaining relevant certifications (including ISO compliance) with the goal of continuously improving our efforts.

Stamping and Fabrication Capabilities

We offer complete fabrication and stamping solutions using high-end, innovative metal stamping and laser-cutting technologies. Our combined capabilities and expertise lend to superior customization and precision across our services.

Our stamping capabilities include the following to meet a range of project needs:

- Blanking

- Progressive die stamping

- Coining

- Bending

- Shallow draw stamping

- Forming

- Piercing

We also offer laser cutting services for projects requiring enhanced precision. Our VyTek FiberCAB 44 Laser System can cut through various metals with greater efficiency while reducing lead times. Additional system capabilities include:

- Achieving tolerances as tight as ±0.002 in.

- Precision cutting using a 3,000-watt fiber optic laser

- The ability to cut aluminum, steel, and stainless steel with thicknesses up to 0.25 in.

- A small laser spot size that allows for high-quality edges with little to no material warping

Additional Services

Our comprehensive solutions go beyond manufacturing. Our secondary services are designed to support our clients’ full manufacturing and process development needs, saving them precious time and money.

As a one-stop shop for metal fabrication, we can provide clients in electrical applications with valuable added services such as:

- Reverse engineering

- Design engineering

- Assemblies and sub-assemblies

- In-house design and development

- Stocking programs with multiple inventory management solutions

- Finishing services (painting, abrasive blasting, and plating)

Materials Used for Stamped Parts for Power Distribution and Control Systems

Our capabilities allow us to work with many types of materials, including:

- Copper

- Steel

- Stainless steel

- Brass

- Beryllium copper

- Phosphor bronze

- Galvanized steel

- Carbon steel

- Platinum

- Titanium

- Aluminum

Quality Assurance

Part of what makes our solutions stand out is our dedication to quality assurance. We enact thorough quality control processes from the beginning to meet stringent industry requirements. Our experienced technicians and quality engineers work to meet or exceed all project specifications. We also implement continuous improvement initiatives with a focus on lean manufacturing.

These quality measures come together to enhance the reliability and service life of components, so customers can enjoy reliable performance long after project completion.

To help maintain quality control, we employ several inspection and testing services:

- Visual measurement

- Optical inspection with MicroVu cameras

- Fiber optic systems

- Infra-red retro-reflective lasers

- Hardness testing

- Destructive and non-destructive testing

We fully document these processes and complete in-depth inspection reports in line with ISO 9001 and IATF 16949 requirements to maintain quality and transparency.

Precision Stamping for Power Distribution and Control Systems

If you’re in need of high-quality metal stamping solutions for your application, you’ll find everything you need here at American Industrial Company. Our extensive capabilities allow us to work with a range of materials and implement stringent quality control measures throughout production to achieve quality results. From prototyping to large-scale production of multi-step parts, we offer the necessary expertise and resources to meet your specifications.

Contact us today to request a consultation or request a quote to get started on your custom stamping project.